High precision measurements from Cimatron creates a stronger process

Company Alpla Group 07/2023

Quality measurement in the machine?

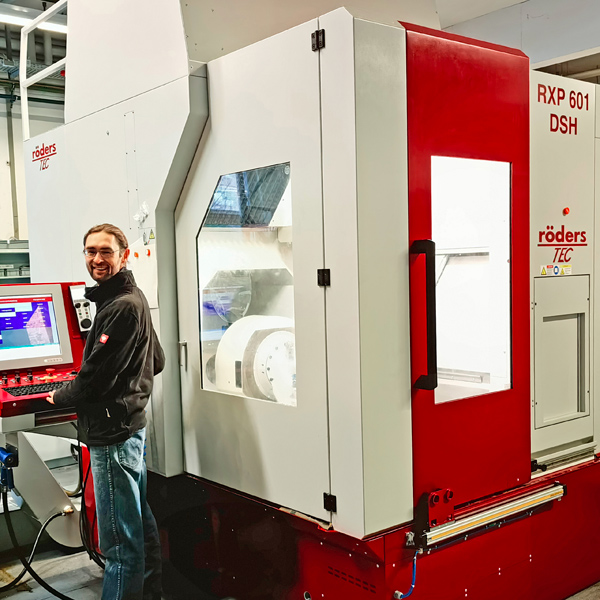

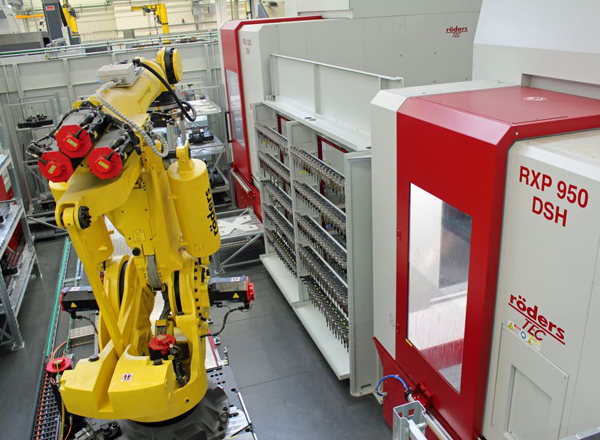

At the Alpla Group in Hard, Austria, the production process was significantly shortened by moving the quality measurement from a separate measuring room to the RXP950DSH from Roeders. Immediately after milling, the workpieces are measured on the machine. The measurement differences compared to a coordinate measuring machine are so marginal that measuring on a coordinate measuring machine could be eliminated.

Download High precision measurements from Cimatron creates a stronger process 07–23

Accuracy and best optics high on the agenda

Efficiency combined with ultra-precise machining

Company Circle 03/2023

What has proven itself in tool and mould making is also suitable for everyday use in general metal cutting. Especially when,

in addition to good cutting performance, high precision and excellent optical quality of the parts are required.

Download Efficiency combined with ultra-precise machining 03–2023

Glass, silica glass, ceramics…

Ultra-precise machining of brittle-hard materials

Company ShapeFab 03/2023

When processing lenses or other structures made of glass or ceramics for applications such as laboratory and medical technology, measuring devices or laser technology, the “classic” three-pronged technology chain of grinding, lapping and polishing using three different systems dominates.

Download Ultra-precise machining of brittle-hard materials 03–2023

Extra large 2000 x 1800 mm with 5 µm stitching gauge: High-precision 3‑axis milling and jig grinding

In many industrial sectors two twinned trends can be observed: customers ask for components with larger dimensions while at the same time requiring enhanced accuracy and surface quality. This not only affects tool and mould making, but also other high-tech application areas such as mechanical engineering, the electronics and metrology sector, or medical technology.

Download High-precision 3‑axis milling and jig grinding 06–23

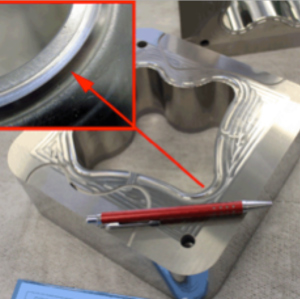

Hard machining above 58 HRC

replaces die sinking EDM

Tool making: efficient lubrication

optimizes tool life

Companies ZF and MHT 10/2022

The performance and efficiency of electric drives depend on the narrowest possible air gap between rotor and stator. The trend towards electrified powertrains thus furthers higher demands on the precision of the stamped parts required for this purpose.

Download Efficient lubrication optimizes tool life 10–2022

Milling, penetration EDM, measuring and washing

Mold making: automated cell integrates multiple technologies

Company Festool 03/2022

In mold and die making, a profound transition is taking place. The previously favored juxtaposition of individual machines requiring high labor intensity is gradually replaced by complex, fully automated cells with integrated handling combining different types of equipment.

Download automated cell integrates multiple technologies 03–2022

Roeders GmbH uses the ZEISS XENOS high-end measuring device for maximum accuracy in mechanical engineering

From Users For Users: Ahead of everyone else with uncompromising precision

Company Carl Zeiss Industrielle Messtechnik GmbH 12/2021

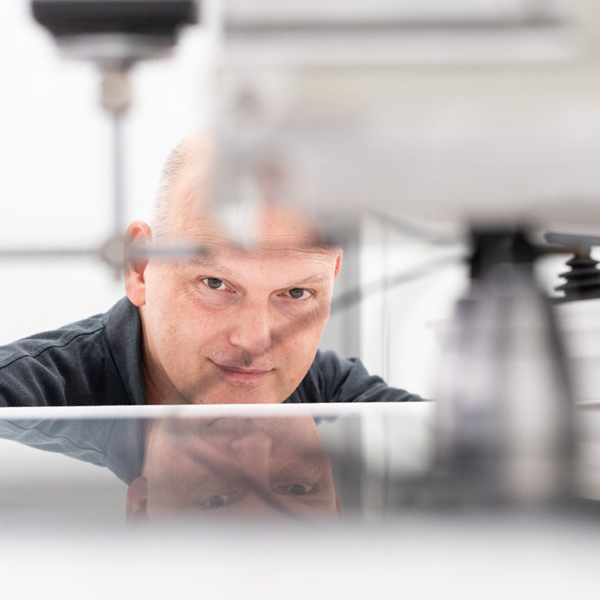

In Soltau, Lower Saxony, highly precise milling and grinding machines are produced in the mechanical engineering department at Roeders GmbH. The tolerances here are sometimes so small that customers were arguing about measured values again and again.

Ultraprecision machining of metals and plastics

Lenses, mirrors, semiconductor technology, lasers, prototypes …

Company son‑x, 12/2021

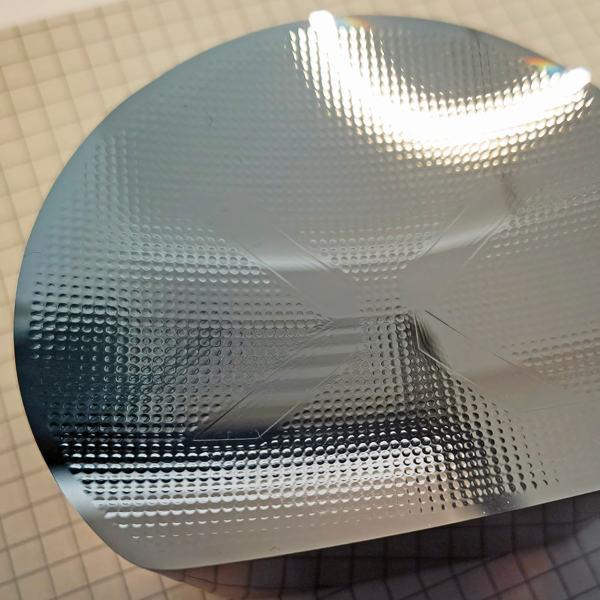

For many optical components, such as lenses or mirrors, the requirements for the accuracy of the contours and the quality of the surfaces are up to a power of ten more stringent than for other micro production processes. Fractions of a micrometer or surface roughness values in the single-digit nanometer range are required.

Download Ultraprecision Machining of Metals and Plastics 12–2021

Short-term production of a finished gearwheel — Flexible gearwheel production with

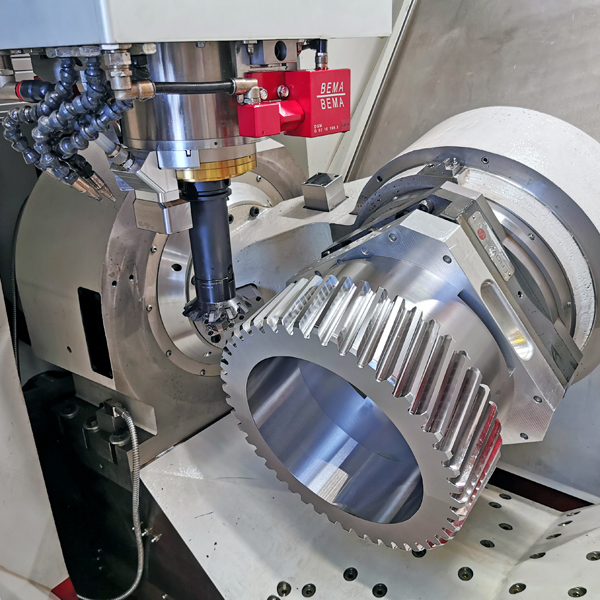

high-precision 5‑axis machining centres

The manufacture of gearwheels for machine building applications usually involves machines especially designed for the purpose. Important techniques include gear hobbing, gear shaping, gear-generating planning, profile milling and profile broaching. Generally, specialized tools whose geometry is precisely adapted to the work-piece are required.

Fully automatic HSC hard machining

Automation in mould making: milling machine manufacturer as development partner

Company Hella, 04/2019

Although complex injection moulding tools are often one-off pieces, systematic standardization of processes and automation of the machining steps in conjunction with the use of suitable machines enables benefits to be achieved relating to both quality and costs.

Milling machines for the high art of mould making What do precision milling centreshave to do with mascara applicators?

Company Zahoransky Automation & Molds, 08/2017

It is hard to find product categories with aesthetic requirements that exceed those of the healthcare & beauty sector. The requirements that such products have to meet encompass all relevant aspects, such as design, colour, surface quality or look and feel. It goes without saying that items produced by plastic injection moulding need moulds that fulfil comparatively stringent quality requirements.

Download Milling machines for the high art of mould making — 177 kB

Highly precise multi-purpose machine for the tool shopMachining center for heavy-duty service in milling and jig grinding

Company Feintool, 12/2015

Feintool is a specialist for fine stamping and forming of precision sheet metal parts for various industrial applications with a world-wide reputation. The top performances its customers require can only be achieved if the entire process chain from the press through to the tool, the consumables and the periphery is carefully designed and optimized from one source.

Download Highly precise multi-purpose machine for the tool shop — 209 kB