Reliably precise on every workpiece

Here is just a short selection of typical applications.

More on YouTube, LinkedIn, Instagram and Facebook

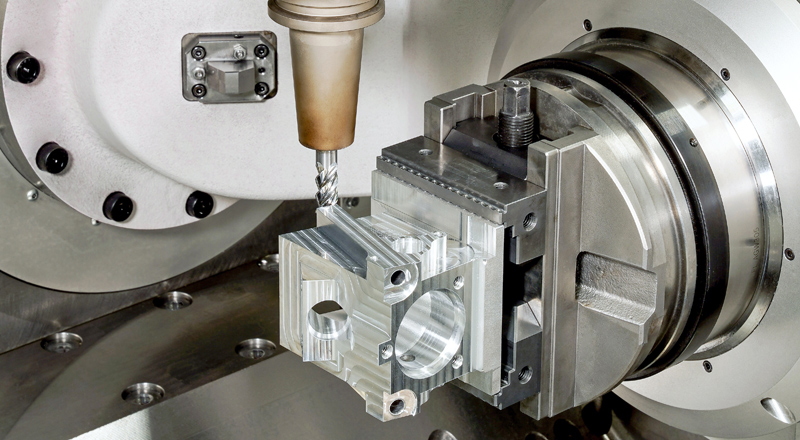

Precision Parts Manufacturing

Consistently reliable precision makes it possible holding narrow tolerances in the production of parts, even when ambient temperatures fluctuate

Jig Grinding

With Jig Grinding a very high level of precision (< 1 µm) and surface qualities (Ra < 0.01 µm) are achieved on Roeders HSC machines. Due to the high stiffness of the machines the combination of High Speed Cutting and Jig Grinding in one machine is possible and results in large cost savings for many applications.

Machining of glass and ceramics

Roeders experience in milling and grinding and the cooperation with customers have lead to an exceptional performance of the Roeders machines for machining glass.

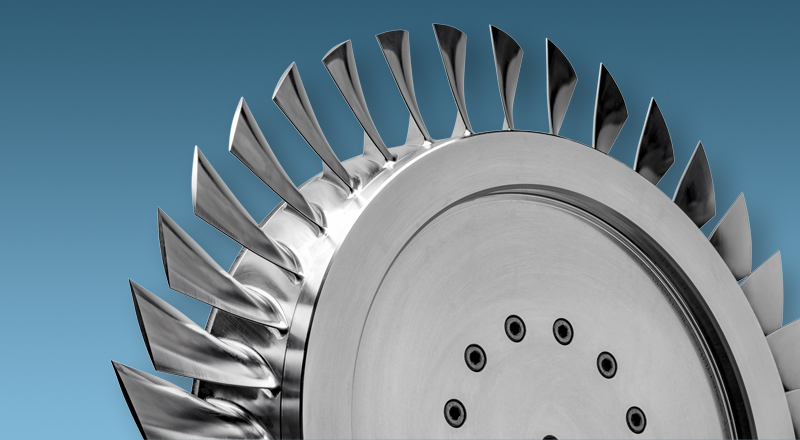

Aeronautics and aerospace

BLISKS, BLINGS or Impeller require smooth surfaces without any steps from the machining process. Direct drives in all axes, 32 kHz drive technology and a special temperature management in the Roeders machines ensure highest dynamics and constant quality also over extended periods. The cost savings compared to standard machining centres may reach 20% and more.

Moulds for fuel cells

Highly precise contours with small inner radiuses and high surface qualities are required on moulds for fuel cells. Numerous customers appreciate especially the high long term precision of the machines from Roeders for the machining operations lasting many hours on one workpiece.

Carbide Machining

For machining carbide the long lasting experience of Roeders in combining milling and grinding in one machine leads to a very high efficiency. High precision and stiffness of the machines allow extraordinary machining results.

Optical components

High-precision plastic injection moulds for optical components, e.g. light-emitting diodes, are a new focus in the wide spectrum of applications for Roeders customers.

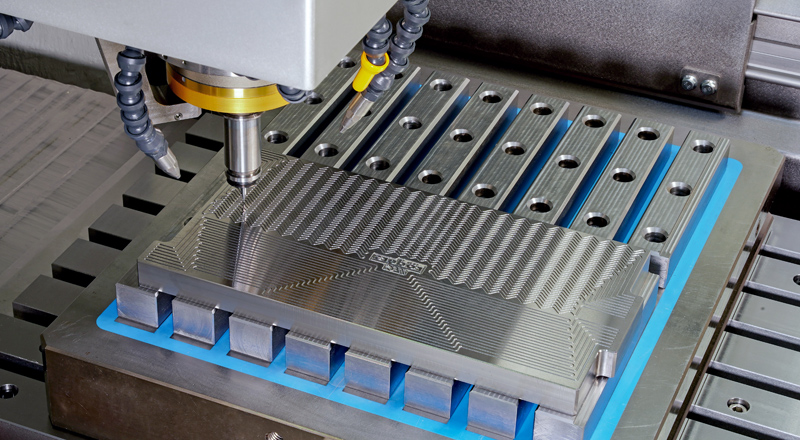

Mould and die making

Micro-mould production with structures in the hundredth-millimetre range, dies or moulds weighing several tonnes, electrodes etc.

Gears

Highly precise 5‑axis, if necessary automated production of different gears as single pieces or in small batches

Watch Industry

Highest qualities at shortest machining times are achieved by high precision air bearing spindles in combination with the direct drive technology of the linear motor machines.

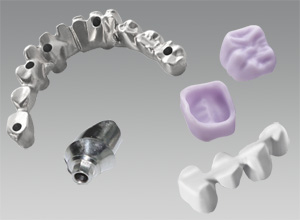

Dental

All materials used in the dental industry can be machined fully automatically and with high precision.

Minting technology

Coining dies are produced down to the last detail by milling, without any need for reworking.

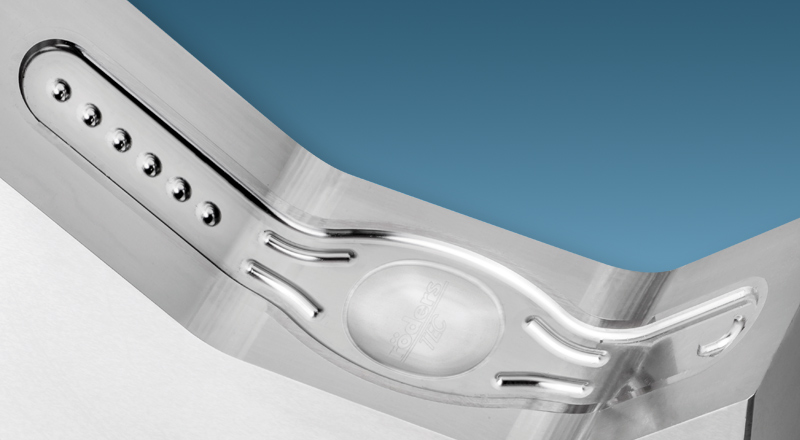

Grinding of a Draw Die

Offset-free five-axis simultaneous machining of a draw die using coordinate chop grinding. The three areas plane, fillet (R 5 mm) and oval opening (46 × 40 mm) were ground in one path with a ceramic bonded CBN. The machining was carried out on a Roeders RXP601DSH milling and coordinate grinding machine.

Impellers

Through the development of special machines for greatest possible accelerations (up to 3g), extremely short machining times can be achieved with the same high quality.

Glass moulds in graphite

Due to the high precision of the Roeders machines machining of mirror surfaces in graphite becomes possible, with Ra values < 0.1 µm.