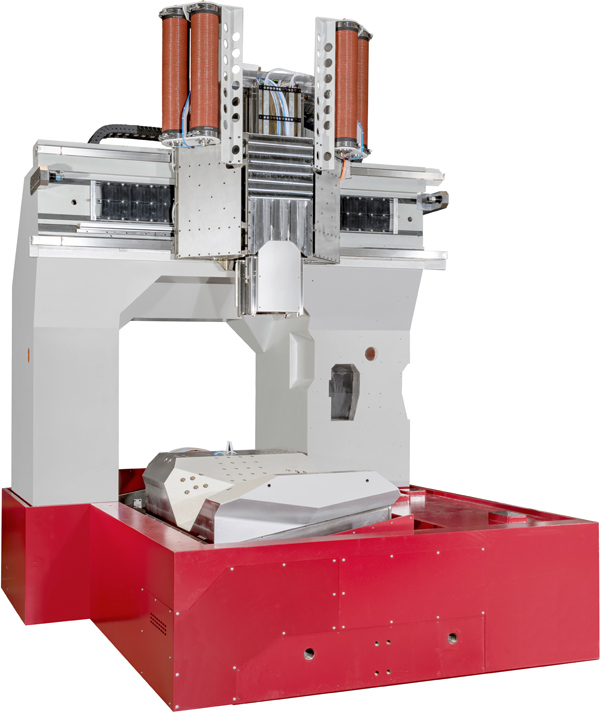

Structural Features

of the Roeders Machines

Very rigid portal design

- Heavy, robust machine frames

- Low moving masses

- Linear and torque motors (direct drives) in all axes

- Easy installation with 3‑point support

Patented frictionless weight compensation

- Constant force over the entire positioning range

- Frictionless vacuum hoses without stick-slip effect

- Optimal for highly precise drive control of the Z axis

Very good visibility

due to large-sized windows and good accessibility to the machining area from two sides; loading with a crane possible

Compact, highly rigid construction

- Linear motors in all axes for highest possible accuracy and dynamics

- No moving parts, no wear, high reliability

- Roller guideways for low friction, low heat generation and, at the same time, very high rigidity

- High-precision linear scales

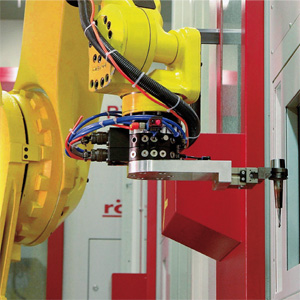

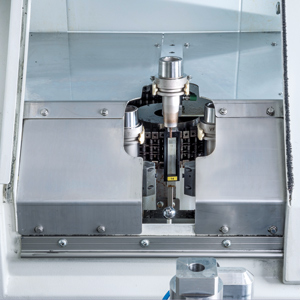

Robot loading of tool changer

- Chain changers also accessible for automatic loading with external tools by a robot or RCM, through a separate lift gate without interrupting machining

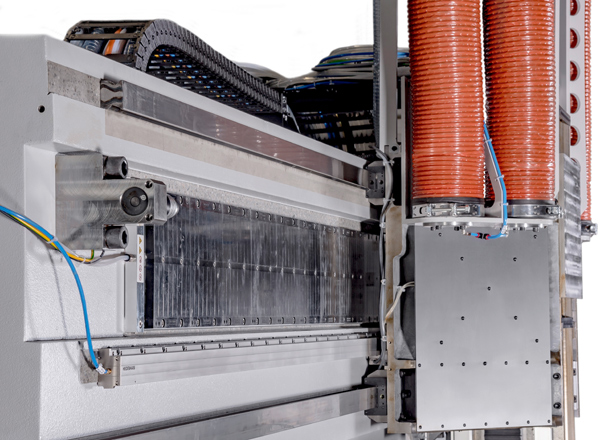

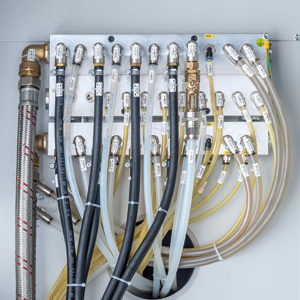

Large number of water circuits

- Machines completely temperature-stabilised, due to a large number of water circuits

- For highest precision the guiding rails and carriages are optionally temperature controled with a water circuit directly through the rails and carriages themselves

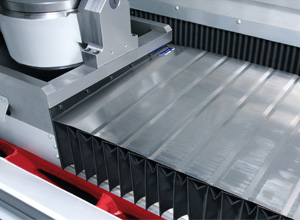

Axis covers

- Frictionless axis covers for best possible dynamics and accuracy

Protection against chips

- Special precautions taken – also during tool change sequences – in order to protect all tool holders against falling chips