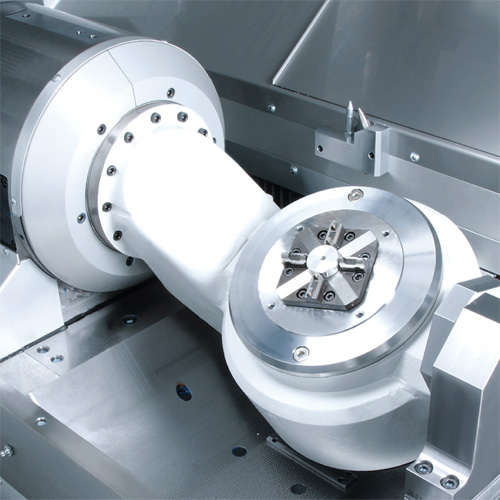

RXP500DSC – 5‑axis machine

Optimised geometry for better machining access in operations with large swivel ranges

- Inertia reduced further compared to the RXP500DS, therefore no break in the C axis

- Workpiece in the centre of the swivel axis

→ only small compensation movements by the linear axes - Special Roeders geometry compensation

| Technical data | |

|---|---|

| Machining range | 450 mm x 455 mm x 240 mm |

| Swivelling range | +/-115 degrees |

| Rotation range | Almost unlimited |

| Table size | 200 mm (integrated chuck optional) |

| Workpiece weight | max. 30 kg |

| Feed | 0–42,000 mm/min |

| Milling spindle (standard) | 42,000 rpm, 14 kW, HSK E40, maximum tool diameter 16 mm (others on request) |

| Tool changer | 21 (linear), optional 35 or more places (chain changer – can be loaded during machining) integrated measuring laser |

| Chip disposal | In 2 chip boxes, optional chip conveyor |

| Machine weight | ~6.5 t |

| Required space | W 2710 mm x L 2350 mm x H 2350 mm |

- Very efficient due to high stiffness and optimum layout of the mass inertia

- Two-sided support of the C‑axis for high stability and precision

- High resolution optical encoders in all axes

- Powerful wear-free direct drives in all axes

- Special Roeders 5‑axis geometry compensation for high precision, also at long lasting machining operations

- Precise temperature control of the machine elements

- For dynamic decoupling, the swivelling direction is at right angles to the X axis

- Windows very close to the machining area, visible from two sides

- Chucks for different pallet systems can be integrated into the C‑table