Extension Of The Possible Applications

through Special Accessories

Medium Distributor

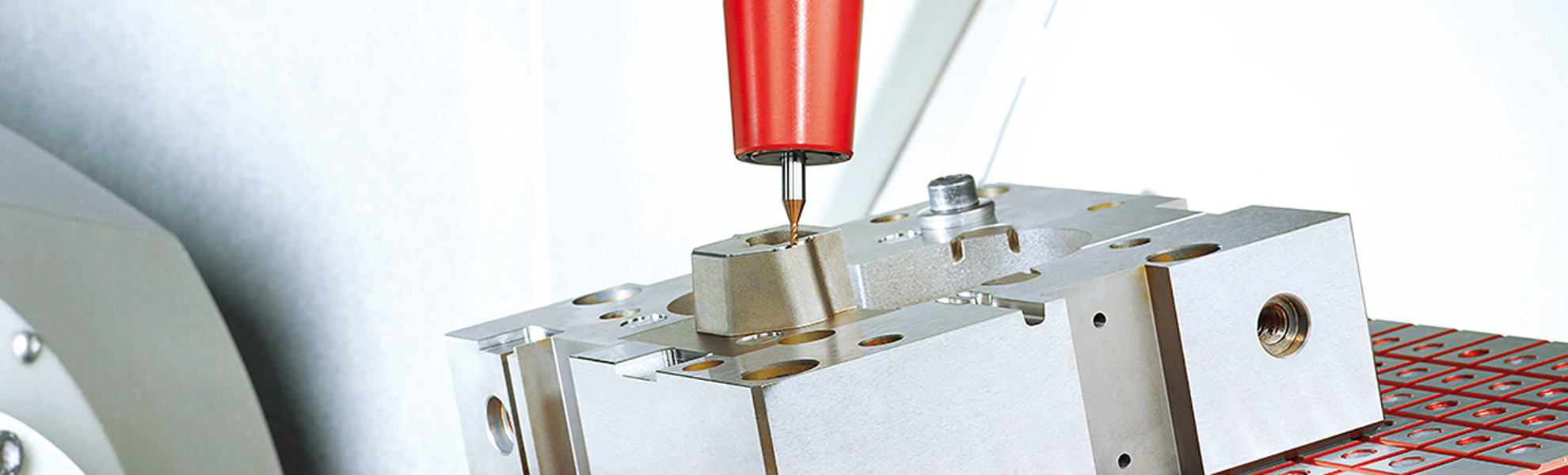

A typical minimum lubrication consists of air jets which blow air containing very small quantities of atomized lubricant, e.g. oil, on the cutting area of the work piece. The German company MHT GmbH has optimized this technology with its specialized Medium Distributor. In manifold applications high qualities on the workpieces and longer lifetime of the cutters have been achieved because the system blows away the chips from the cutting area and provides for very precise lubrication. After machining the workpieces usually are dry as the lubricant vaporizes during the cutting process.

Shrink technology

Roeders started using heat shrink technology for HSC machining as early as 1992. With regard to concentricity and rigidity, the heat shrink technique is unmatched even today. Roeders offers its own shrinking device and tool holders for all types of spindles.

Additional rotary axes

1‑axis or 2‑axis rotary tables with modern direct drive technology are quickly attached for different applications.

Tool holders

Important for the machining results are also the tool holders. They determine the concentricity of the tool and therewith the achievable quality of the workpiece with respect to precision and surface quality. Therefore, Roeders offers high precision tool holders and may also give recommendations.

Suction devices

Roeders offers powerful suction devices with all machine models for graphite, ceramics, oil mist, emulsion etc. with special filter technology.

User-specific work piece clamping technology

For special applications, for example in automated production, Roeders engineers develop specific clamping devices for directly clamping the workpieces in the machine witout any pallet system.