Automation

for Absolute Cost Minimization

With the Roeders Automation the maximum in cost reduction in dental machining is achieved. Proven solutions allow for a reliable production also at very high quantities. A simple and easy to operate software controls the complete system and insures clarity at all times, optionally also in the entire laboratory.

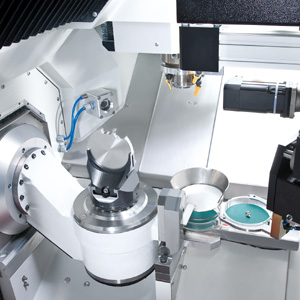

Automatic loading of raw blocks

- Loading of Roeders holder with fixed chromium cobalt disc into the machine

- Automatic clamping on the rotary axis

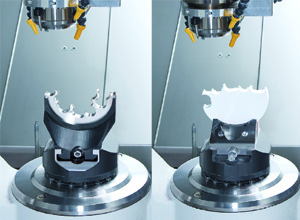

Automatic separation of the restorations

- Separation of the dental works into cups

- Funnel and cup positioned below the disc

- Automatic cut-through of the pins

Minimal non-productive times

- Minimization of the cup exchange time in the machine (empty against filled)

- Cushioned cups for avoidance of damage to dental works

Optimum material utilisation

- Efficient material utilization by one sided clamping of discs

- “Complete” machining of disc, up to 30% more units per disc

Chip identification in the magazine

- Automatic checking of the magazine setting

- Optional labelling of the cups with RFID chips allowing for automatic referencing of the machined dental works to the cup ID by the software

Chip identification in the laboratory

- Use of the cup identification in the entire laboratory, for example at manual workplaces

- Identification of the machined dental work in the cup with a handheld chip reader is possible anytime

- Integration of a printer for labels or other devices possible