Hardware For The Automation

The hardware for the automation should match the requirements of the automation application as good as possible in order to optimize costs, necessary space and efficiency.

Main criteria are:

- Direct clamping of the workpieces or on pallet?

- Workpiece weights and sizes

- Machining times per workpiece

- Supply of the machines with external tools from the magazine necessary?

- One or several machines to be automated?

- Later extention of the automation by further machines desired?

- Needed access to the automation and corresponding security concept

- Manufacturing technologies to be automated

In order to cover the diversity of customer requirements, Roeders has developed a large range of automation solutions over the years. Starting with a simple, integrated space saving solution, all the way to robots on rails with numerous machines of various manufacturing technologies, all project types with different requirements can be realized.

RCI‑P

Machine-integrated automation

RCE

Cost-efficient automation of one or two machines

RCS

Compact, flexible automation of one or two machines

RCF

Flexible linear multi-machine automation

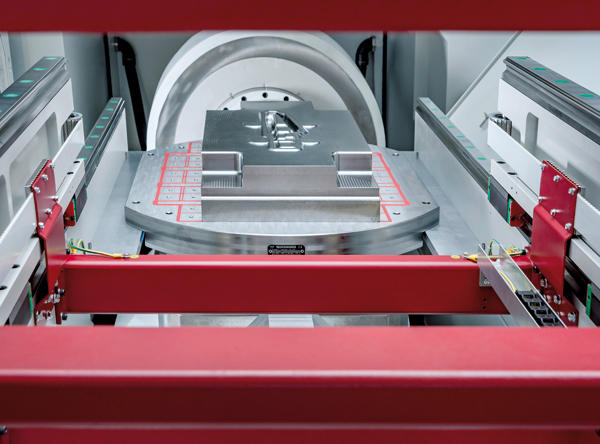

RCH

Heavy-load automation up to 1500 kg

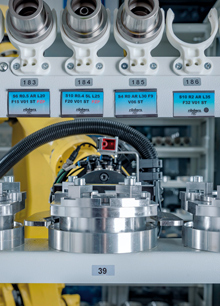

RCR

Robot cell, versatile and short installation times

Robots

Highly flexible, suitable for auxiliary functions or direct clamping of workpieces without pallets