Integration of Numerous manufacturing Processes

Roeders has already integrated numerous manufacturing processes into automation solutions. Upon demand a multistage machining process is possible. This means that a workpieces undergoes different machining operations in the machines. Electrodes for example are produced first by milling, cleaned, measured and subsequently used as electrodes in EDM, all in one automated cell.

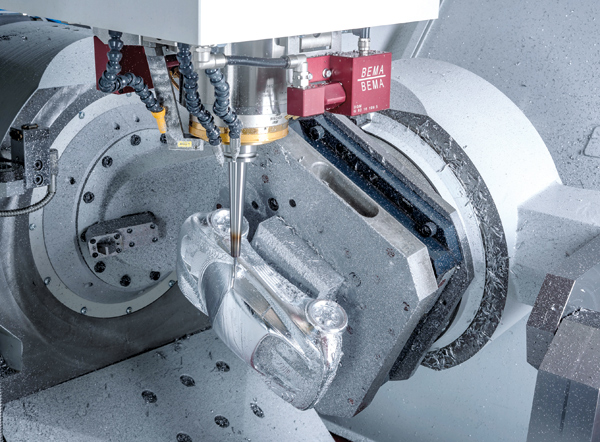

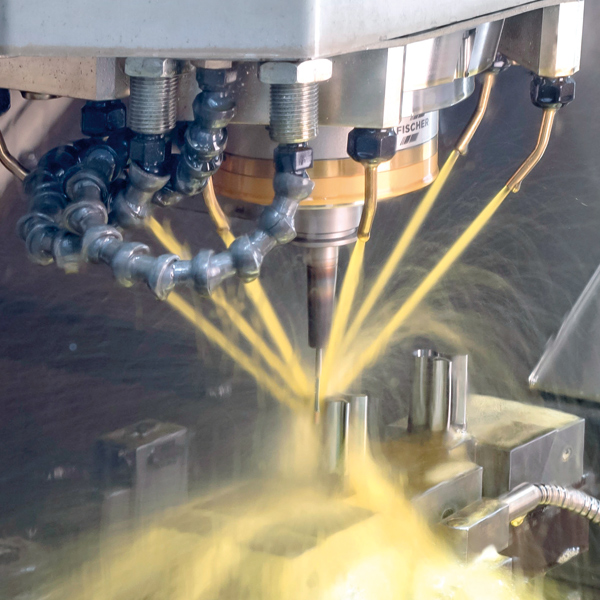

Milling

Before starting a job checking of the availability of the tools. Automation of machines with other controls than Roeders possible.

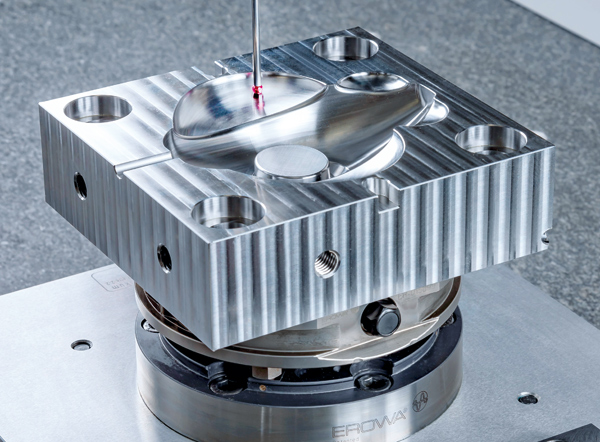

Measuring

Interfaces to numerous measuring machines existing: Zeiss, Mitutoyo, Hexagon, Wenzel and others. Measurement of zero point coordinates or orientation of the workpiece for the machining operation or quality control after machining.

Grinding

Integration of jig grinding, profile grinding, contour grinding etc.

EDM

Experience in automation with machines from Sodick, OPS Ingersoll, Makino, Exeron, Zimmer & Kreim. Interfaces to the individual programming software for the EDM machines already exist. Import of electrode data possible.

Wire cutting

Interface to wire cutting machines available.

Washing / cleaning

Washing, cleaning and drying devices from MAFAC or Zimmer & Kreim already integrated

Manual operations

Programmed integration of manual operations like visual inspection into the workflow of a work-piece in an automated cell possible