Machining Spindles at Roeders

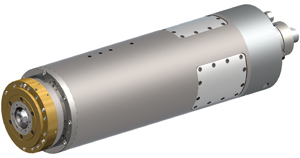

For a high efficiency of the machine in the user-specific application the spindle choice is essential. Therefore, Roeders offers an exceptionally wide range of main spindles.

For a high efficiency of the machine in the user-specific application the spindle choice is essential. Therefore, Roeders offers an exceptionally wide range of main spindles. By means of a standardized interface, which has been optimized over many years, especially thermally, the main spindles are mounted in the Z‑axis of the machines. This allows for a cost-effective change to another spindle type at a later time, in case the application for the machine changes. Options like vector control, axis cooling for high precision, lead throughs etc. are available as needed. Roeders always has spare spindles in stock for all spindle types.

In case an application requires very high rpm and also a relatively powerful spindle, Roeders offers the possibility to equip a machine with two main spindles. Further information can be found at: Double Spindle machine – Option Z2.

| Tool Holder | Max. rpm | Torque | Bearings / Lubrication | |

|---|---|---|---|---|

| HSK E25 | 80,000 | 0.6 Nm S1 | air bearings | |

| HSK E25 | 60,000 | 0.6 Nm S1 | air bearings | |

| HSK E25 | 50,000 | 0.9 Nm S1 | ball bearings / grease | |

| HSK E32 | 60,000 | 3.4 Nm S1 | ball bearings / air-oil | |

| HSK E32 | 40,000 | 2.4 Nm S1 | ball bearings / grease | |

| HSK E40 | 45,000 | 5.5 Nm S1 | ball bearings / axis cooling / air-oil | |

| HSK E40 | 42,000 | 5.9 Nm S1 | ball bearings / air-oil | |

| HSK E50 | 36,000 | 12.4 Nm S1 | ball bearings / axis cooling / air-oil | |

| HSK E50 | 36,000 | 12.4 Nm S1 | ball bearings / air-oil | |

| HSK F63/E50 | 30,000 | 21.0 Nm S1 | ball bearings / air-oil | |

| HSK A63 | 30,000 | 21.0 Nm S1 | ball bearings / air-oil | |

| HSK A63 | 24,000 | 67.0 Nm S1 | ball bearings / air-oil | |

| HSK A63 | 22,000 | 101.0 Nm S1 | ball bearings / air-oil |