Roeders Precision Technologies

PRECITEMP®

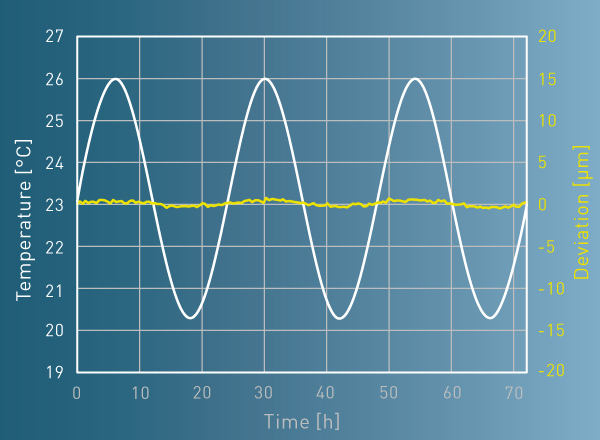

The main reason for dimensional deviations on workpieces are temperature fluctuations in the machine or the environment. With PRECITEMP® I, II or III this is no longer a problem. Depending on the requirements, the machine can be configured to the necessary level of precision by comprehensive tempering and software compensation with the PRECITEMP® I, II or III modules if ambient temperatures are not constant, as is often the case in workshops even if they are air-conditioned.

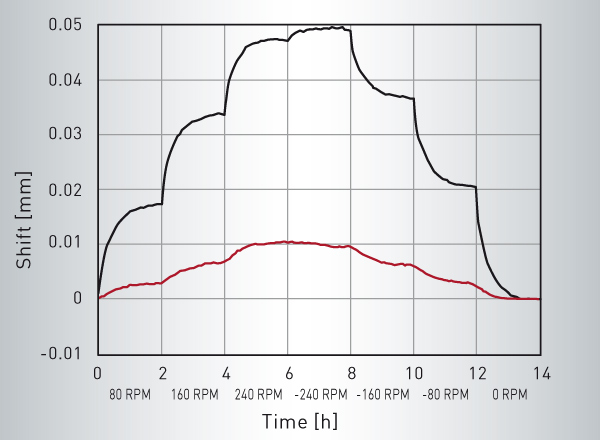

For rotary axes with torque motors it is common to temper the motors with water. Roeders goes one step further and optionally also tempers the bearings and the machine table in the rotary axes. Dimensional deviations at higher speeds are thus significantly reduced.

(Only available for RPT machines)

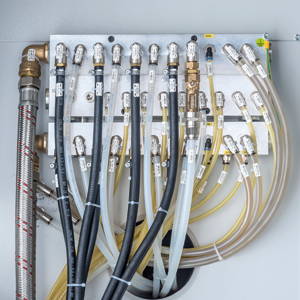

- Machines completely temperature-stabilised, due to a large number of water circuits

- For highest precision the guiding rails and carriages are optionally temperature controled with a water circuit directly through the rails and carriages themselves