Mould and Die Making

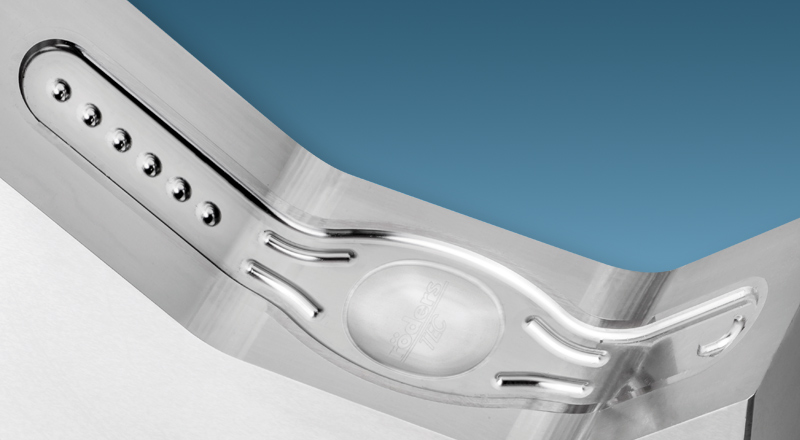

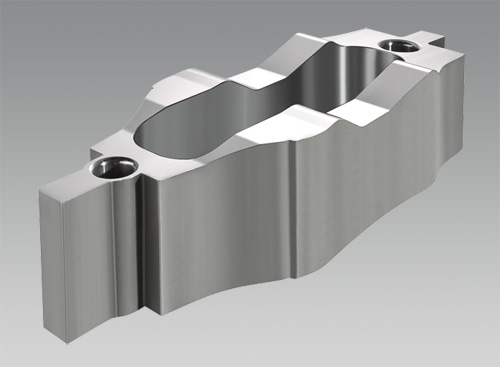

Liquid Silicon Rubber moulds

Highly precise 5‑axis machining, no rework of parting surfaces necessary

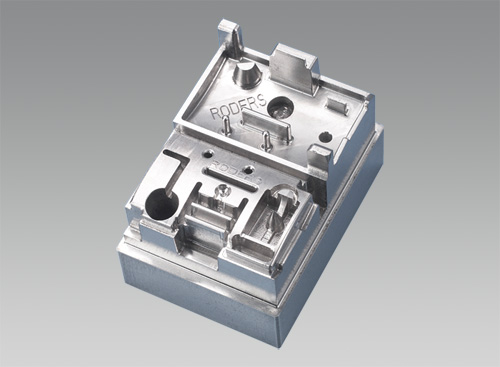

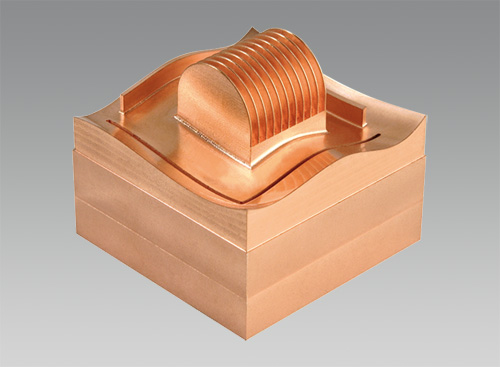

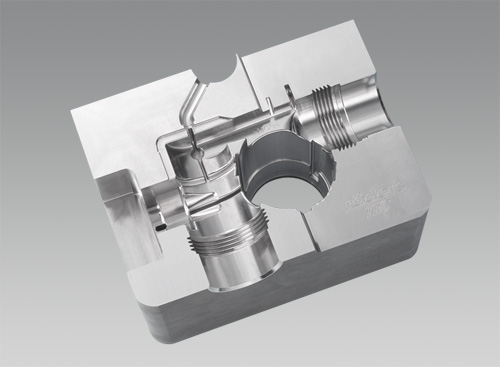

Die casting moulds

Die casting moulds are completely (roughing and finishing) machined with HSC directly in hardened steel. Roeders HSC technology reliably achieves a surface quality and accuracy which makes bench work unnecessary, even at mould parting surfaces.

Die for chain links

Weighing 1 t, this die was machined on the RXU1200 in 50% of the time previously needed

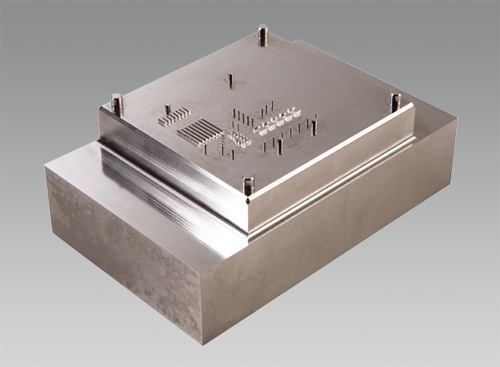

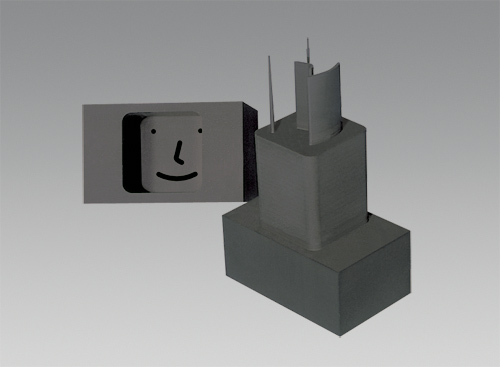

Micro-moulds

for the chip industry and other sectors

Engraving width and depth 0.05 mm

Injection mould

for a swivel-chair cover; dimensions approx. 1 m x 1 m

Insert for reflector injection mould

Through the constant optimisation of all machine components,surfaces can now be produced in “polished quality”.

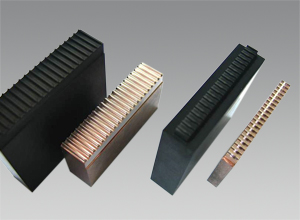

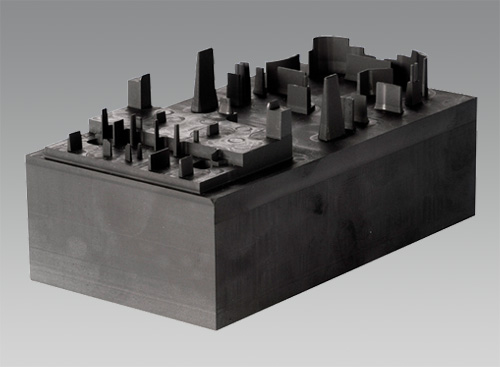

Electrodes

Milled with 5‑axis machines without any reworking

Electrodes

for connectors

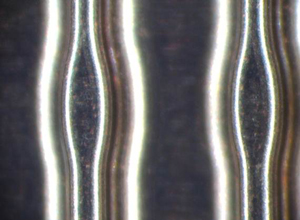

Detail

of electrodes for connectors above, smallest cutter Ø 0.8 mm, achieved Ra = 0.1 µm

Electrodes

Milled with 3- and 5‑axis machines without any reworking

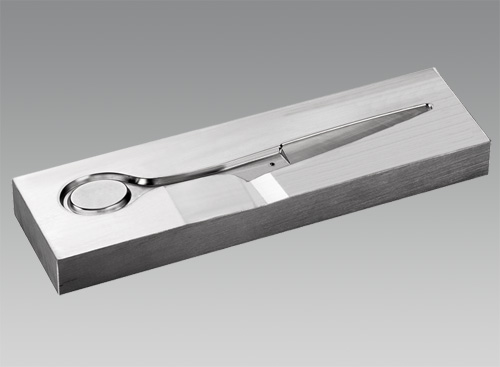

Tools for sheet metal forming

HSC milling and jig grinding with high precision in a single set-up

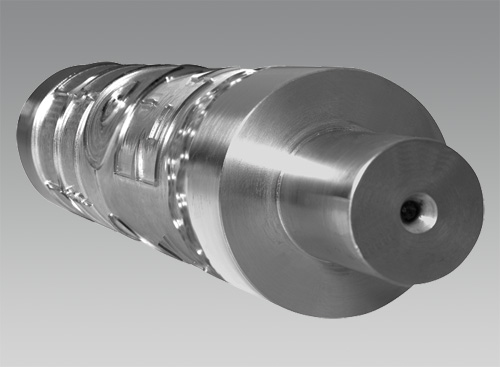

Cutting rollers

Special software available for 4‑axis carving

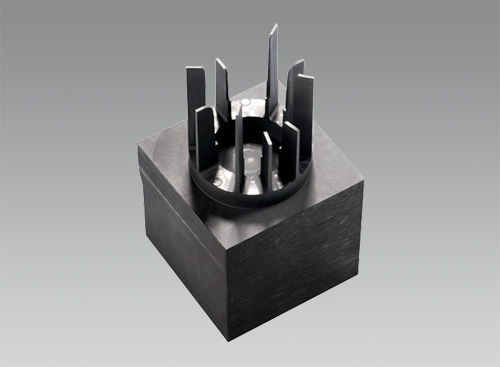

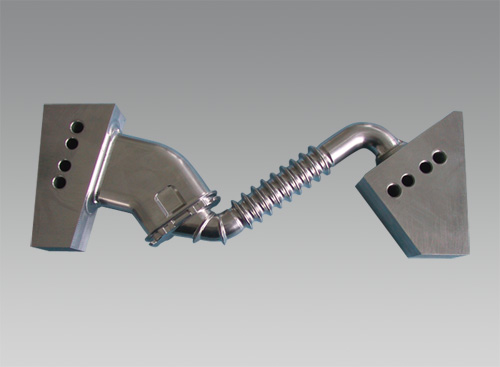

Rubber moulds

Machining from all sides in one set-up

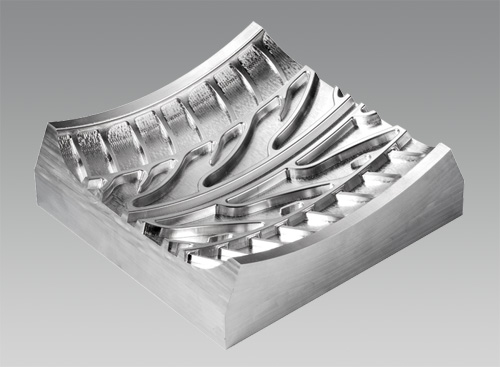

Tire moulds

Extreme dynamics for shortest machining times

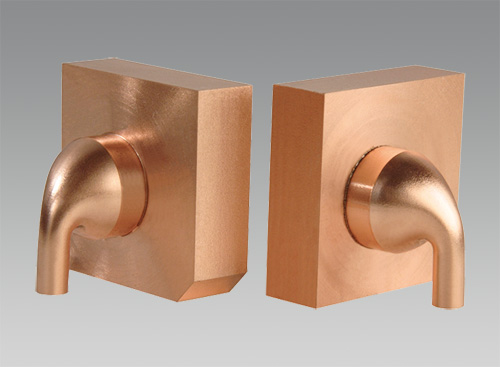

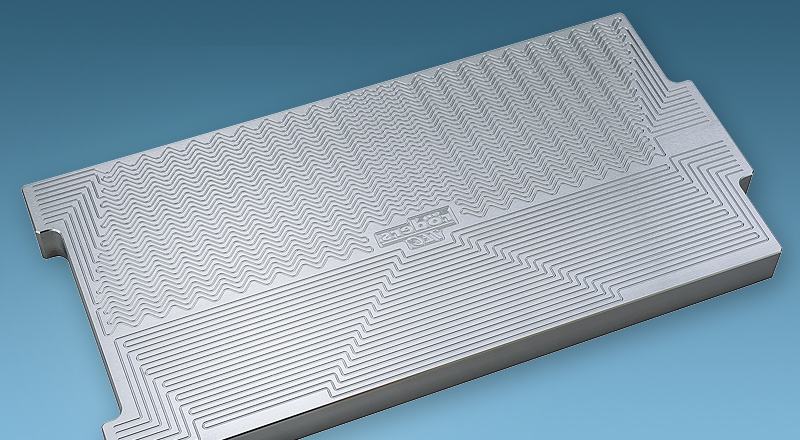

Moulds for fuel cells

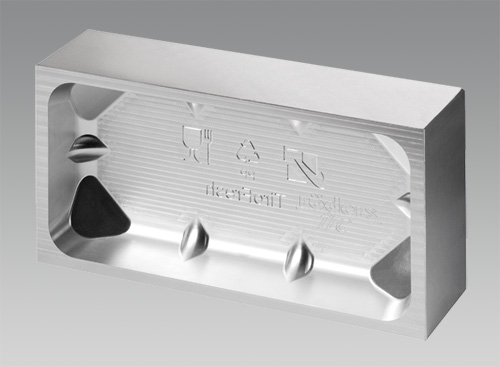

Cutting and forming die

HSC milling and jig grinding (tolerance 1 µm) in a single set-up

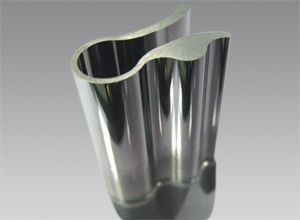

Blanking punch

Tolerance < 1 µm over the full height

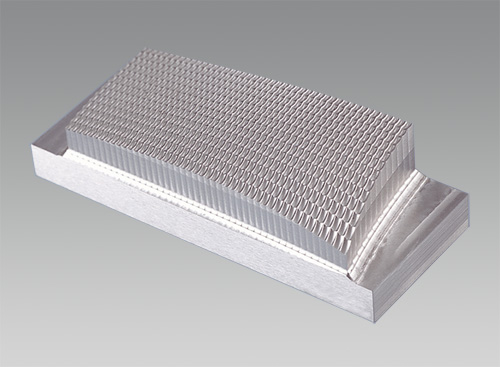

Package moulds

of high-tensile aluminium

Precision forging dies

High rpm for producing small corner radii

Injection moulds

with high precision in every detail

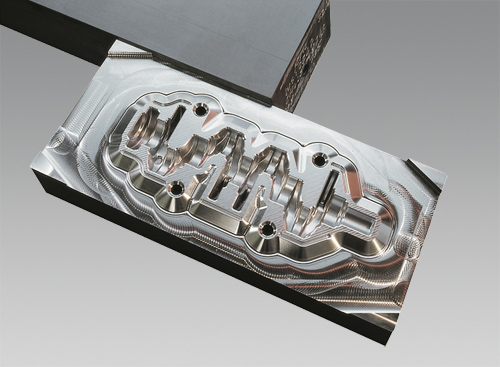

Crankshaft forging dies

in high-tensile steel with extreme cutter lengths, finish-machined

Complex plastic injection moulds

no longer requiring spark erosion

Embossing dies

finish-machined in 70 HRC

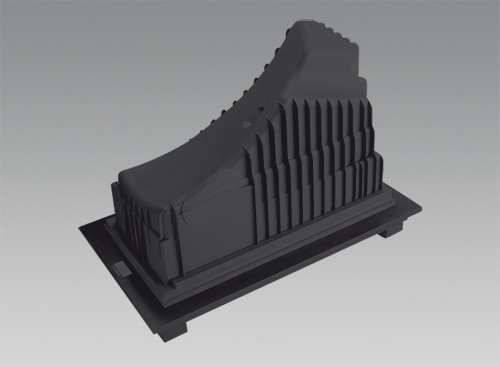

Shoe moulds

Aluminium cutting with very short milling times