RHP Machines

The RHP machines differ from the RXP machines in terms of the guideway concept. Hydrostatic guideways in all axes improve the running performance significantly:

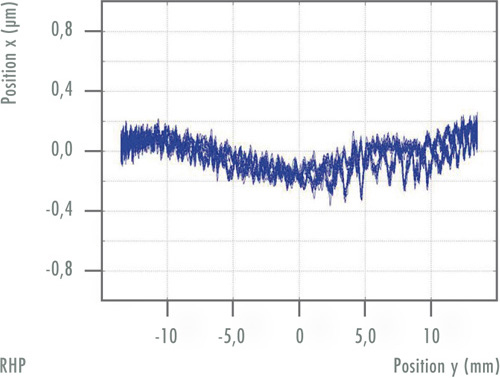

- Micro-movements across the travelling direction of the axes in the sub-micrometre range, as encountered with roller guideways, are reliably prevented.

- The controlled hydrostatic oil film between the moving slide and the guideways provides additional damping.

- The precise temperature control of the hydrostatic oil is effective directly at the guideways, prevents temperature fluctuations and hence thermally caused deformation of the machine geometry.

- Because the axis covers and weight compensation for the Z axis (patented) are optimised for minimum friction, the axes exhibit an ideal drive control response.

The fundamental technology of the RHP machines corre-sponds to that of the RXP series: linear motors in all axes, Röders RMS6 control, exact temperature stabilisation, compensation of the spindle elongation etc.

- Hydrostatic axis construction with hydrostatic guideways pretensioned by the magnetic field of the linear motor

- High-precision glass scales with a position resolution of 1 nanometre

- Wear- and friction-free

Less micro-movements across the travel direction and therefore a much smoother running of the axis slide with hydrostatic guideways in comparison to guideways with roller or ball bearings

Options

The manifold options for the RXP series are also available for the RHP machines, e.g. rotary swivel units for 5‑axis machining etc. The RHP machines are excellently suited to the combination of HSC milling and grinding.

3 axes: