Optical Components

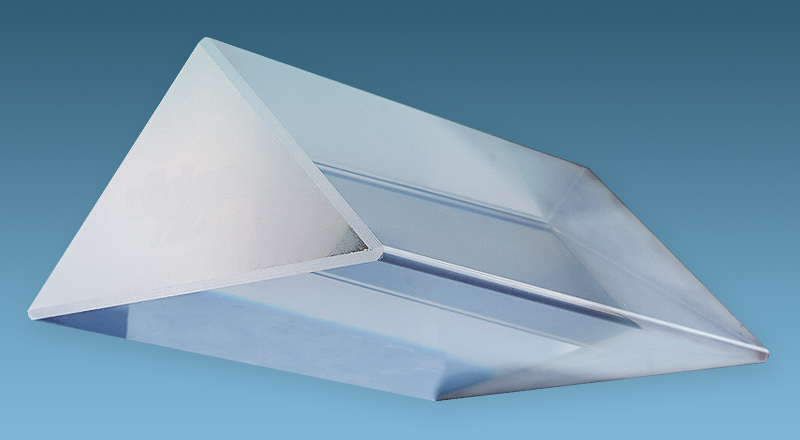

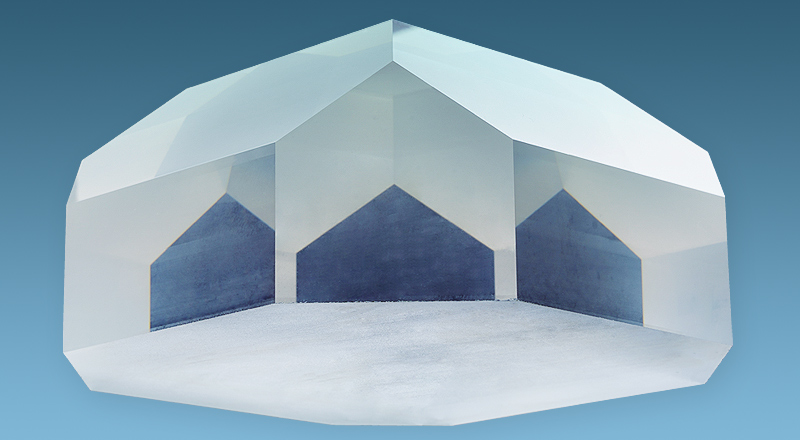

Glass prisms

Machining of optical glass prisms with extreme angular precision below 2 arc seconds, also for large prisms. Roughing and finishing in one set-up on 5‑axis and respectively 3‑axis machine

Since beginning of 2012 due to new developments in drive and spindle technology extremely high surface qualities are achievable, which are comparable to such produced on ultra-precision machine tools (UP machines).

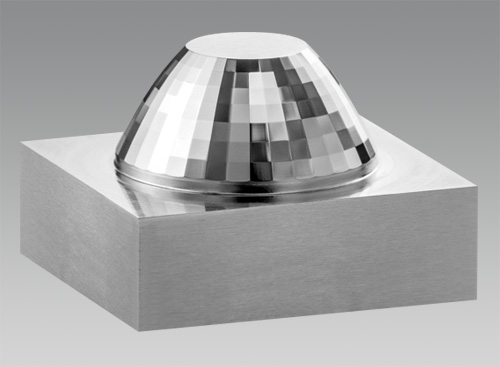

Reflectors

Produced with air bearing spindle on the machine

- Precision +/- 1 µm

- Surface quality Ra = 0.005 µm

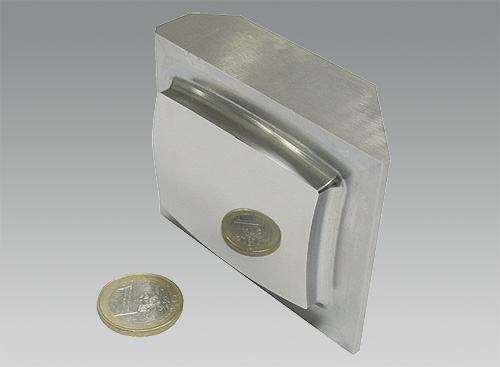

Insert for injection mould of a mobile phone display

Entire surface produced with Ra < 0.01 µm on the HSC machine

Surface quality after milling

with a 4 mm ball nose cutter, surface quality Ra < 10 nm, machining with small step over from tool path to tool path

Detail

of reflecting workpiece above