Precision Parts Manufacturing

With Roeders machines, you reliably and permanently hold very small tolerances in the parts production. If necessary, you can combine milling and grinding in one set-up for optimal results. The PRECITEMP® technology developed by Roeders over many years ensures a thermally robust machine structure, so that no thermal drifts occur even with fluctuating ambient temperatures and the machine zero points remain stable and unchanged. In this way, you create the conditions for a highly efficient automation with lowest staff requirements possible. Roeders offers numerous handling devices and software solutions that have been proven for many years.

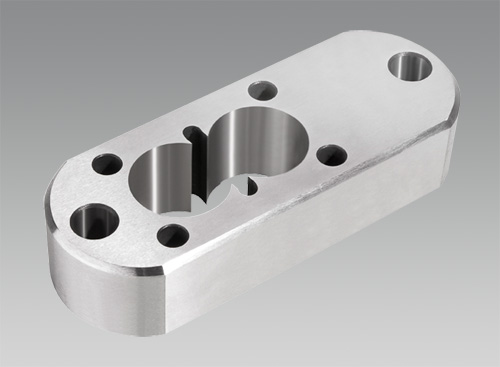

Throttle valve housing

Tolerances down to 0.01 mm, surface quality Ra 0.2 µm

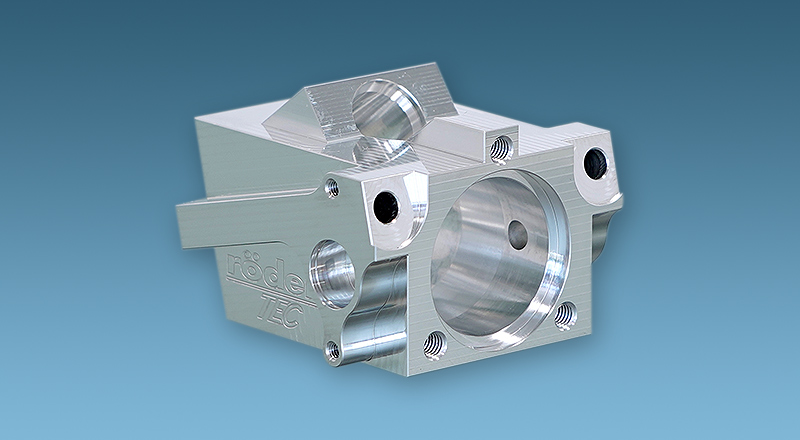

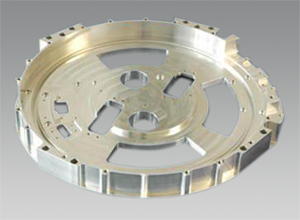

Housing for a hydraulic pump

Tolerances of the “double holes” (position and roundness) < 1 µm

Medical

Implant machined from solid block

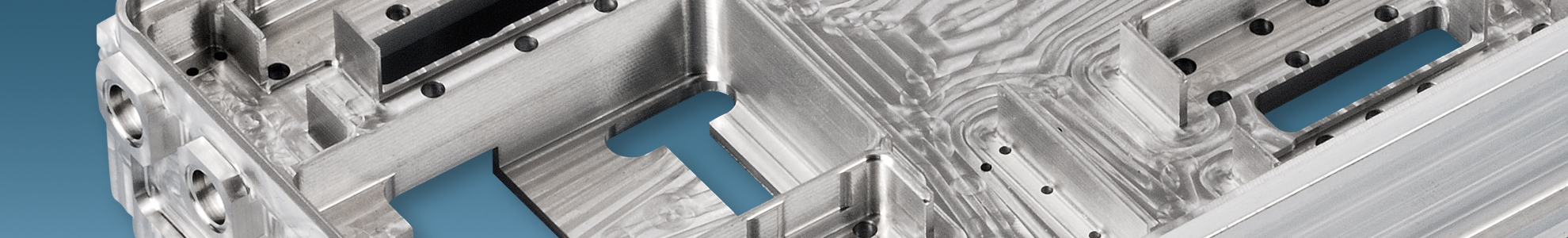

Neck plate for blow mould

produced in two set-ups, tolerances 0.01 mm

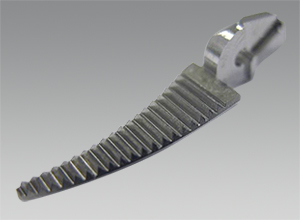

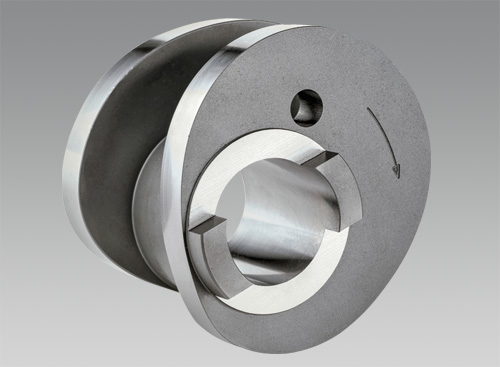

Camshaft

produced by milling and grinding in one set-up, tolerances smaller than 1 µm

Reading head holder for linear scale

machined in 2 set-ups, tolerances 0.01 mm

Housing of a jaw scanner

high surface quality for coating necessary

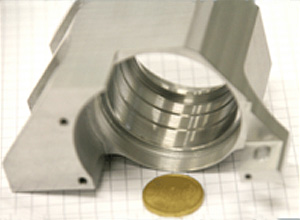

Optical mount for precision lenses

Series production, machined from the solid, roundness < 2 µm

Small batches and prototypes

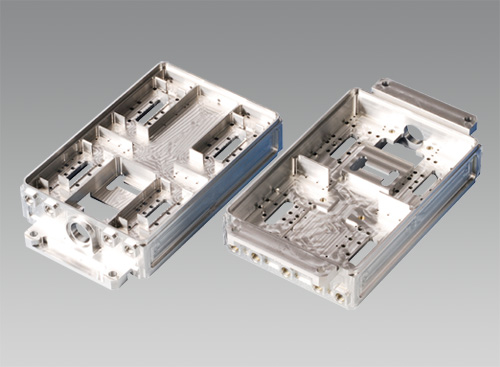

Housing for electrical components

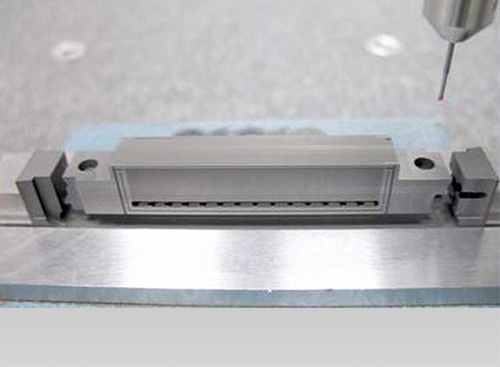

Printing head for high-performance printers, machined in graphite

Fully automated high-precision series production

Watchcase,

completely machined

Design study

finish-machined in one set-up from 5 sides

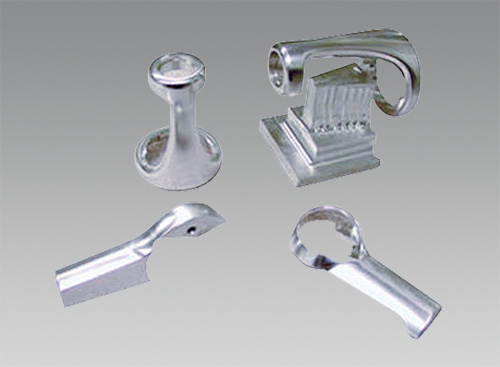

Small batch – automotive

Gear knob and tank cap machined from the solid in 5 axes, to save the mould costs for small quantities

Small batch – bicycle parts

Machined from the solid in 5 axes