Technology for Jig Grinding

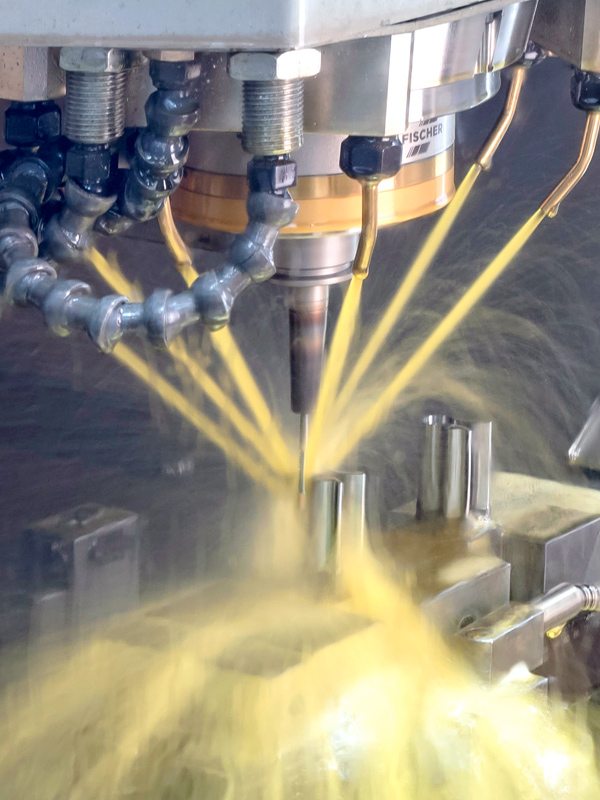

- Precisely temperature-controlled, flushing grinding oil

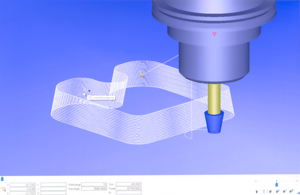

- Chop grinding with slow contour feed rate

- Contour grinding with slow Z‑motion and high feed rate

- High surface qualities possible with Ra < 0.01 µm

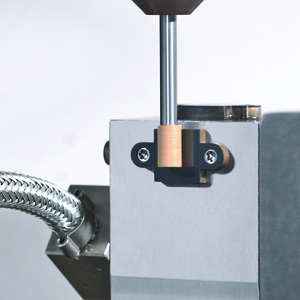

- Check measurements with the automatic 3D touch probe of the machine

permit the production of minimised tolerances for the workpiece, even in unattended operation

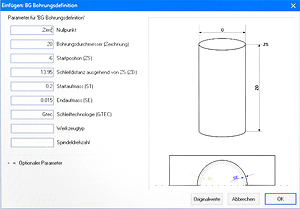

- Very simple user interface for input of the grinding parameters at the control

- Cycles for chop grinding and for contour grinding with slow Z‑motion available

- Externally programmed or constructed contours may be imported

- Also conical contours are easily programmed and machined, incl. dressing of the wheel

at the rotating dressing spindle

- Special cycles available for dressing

- Preliminary measurement of the grinding wheel in the measuring laser for a “rough measurement”

of the grinding wheel

The contact measurement is used for

- precisely measuring the grinding wheel on diamond surfaces

- measuring the workpiece

- monitoring the grinding process

- Special precisely temperature-controlled and fine-filtered grinding oil for optimal grinding results

- Reliable two-channel extinguishing equipment for the entire machining area