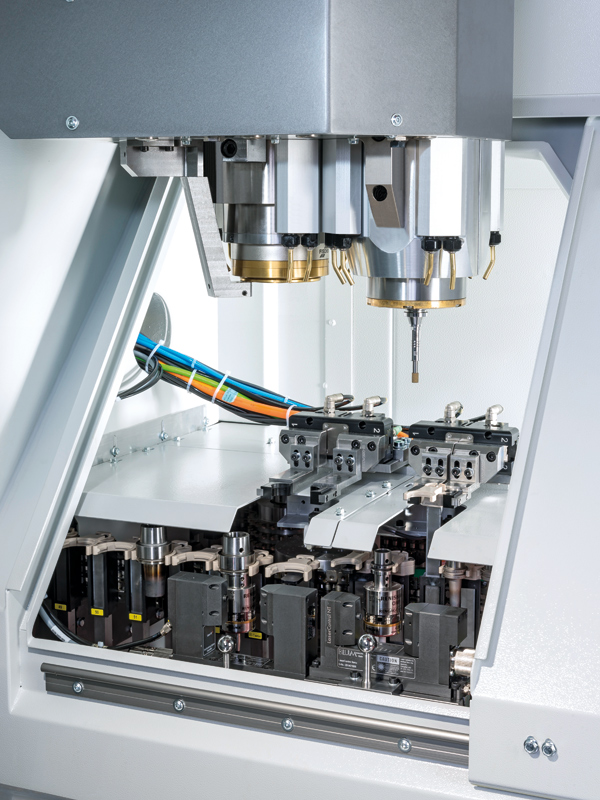

Double Spindle Machine – Option “Z2”

In some applications the choice of the main spindle is difficult, because either the maximum RPM of the main spindle is not sufficient or the maximum tool size allowed in the spindle is not large enough. This affects especially machines for jig grinding, in case very small radii, for example in small holes, are to be machined with very high rpm, but also where larger tools are required for other operations.

In such cases, Roeders offers the possibility to equip a machine with 2 main spindles, one more robust for larger tools and one with high rpm, for example:

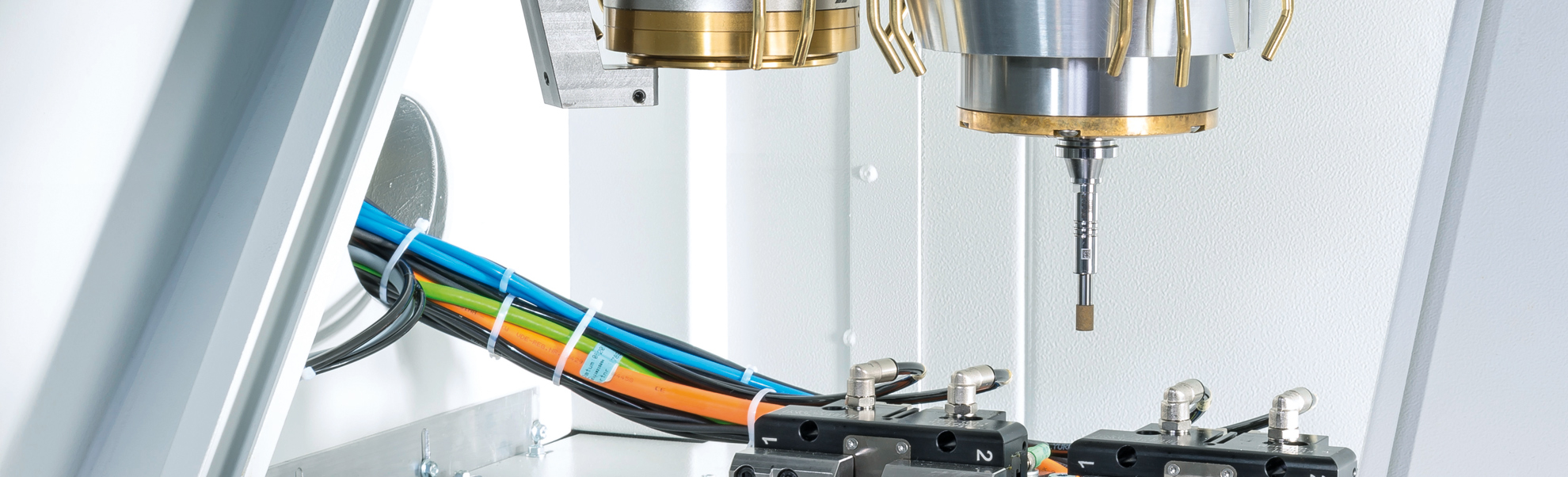

- Spindle 1: with ball bearings, HSK E50, 36,000 rpm max.

- Spindle 2: with air bearings, HSK E25, 80,000 rpm max.

Both spindles are fully integrated in the machine so that the automatic tool changer, laser measurement, different coolants, 3D touch probe and in jig grinding machines all of the equipment for dressing, sound detection etc. are available for each spindle.

The axes of both spindles have a short distance to each other, but the spindles are highly precisely tempered with several cooling circuits. This ensures that the distance between the spindles and the positions of the spindles remain absolutely constant. As a result, in applications where both spindles are used a very high consistency of the work piece origin is achieved. Two spindles are utilized for one work piece set-up.

The option “Z2” currently is available for the machines RXP501, RXP501DS, RXP501DSC, RXP601DS, RXP601DSH, RXP801, RXP950, RXP950DSH and for all RXU machines. In the RXP machines the distance between the two spindle axes is 150 mm, in the RXU machines the distance is 225 mm.

Other machine models may be equipped with two spindles upon request.

Tool changer for two main spindles with different HSK holders