Job Or Cell Management

RMSMain

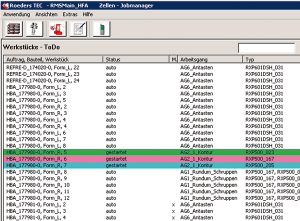

The core of automation is the job management software, in case of automation of several machines in one cell it is also called cell management. RMSMain is easy to operate and fast. Manual input is minimized as much as possible. Individual software modules may flexibly be combined with solutions of other suppliers via numerous interfaces (umati, OPC UA, XML, TCP/IP). Only a small choice of the functionalities of the RMSMain is shown.

CAM-Import

By clever programmed Post Processors the jobs for machining the individual workpieces are automatically prepared in the CAM-system. The jobs only have to be taken over in RMSMain. Manual input is avoided.

Chipidentification / Set-up

The assignment of a pallet with a blank workpiece or a pre-machined workpiece to a machining job is accomplished within seconds.

Interlinked machining processes

In cells with several machines it is possible to define a throughput for a workpiece with different machining operations in different machines.

Administration of blank workpieces

In the production of electrodes but also in other applications standardized blank workpieces are often used. They have standardized sizes and correspond to defined blank workpiece types. With the chip-ID the blank workpiece type is identified during set-up. Then the blank workpiece may be put anywhere into the magazine. The automation recognizes the available blank workpiece type by reading the chip-ID on the pallet. The RMSMain automatically requests the blank work-piece type programmed in the job and makes the automation load it into the machine. Optionally, before the machining of the workpiece starts a check by measuring the blank workpiece with the touch probe is possible. In case an operator has made a mistake with the identification of a blank workpiece type this will surely be detected. Alternatively, an automatic measurement of the blank workpieces in the automation is feasible, for automatic recognition of the blank workpiece type and sorting out blank workpieces with wrong dimensions.

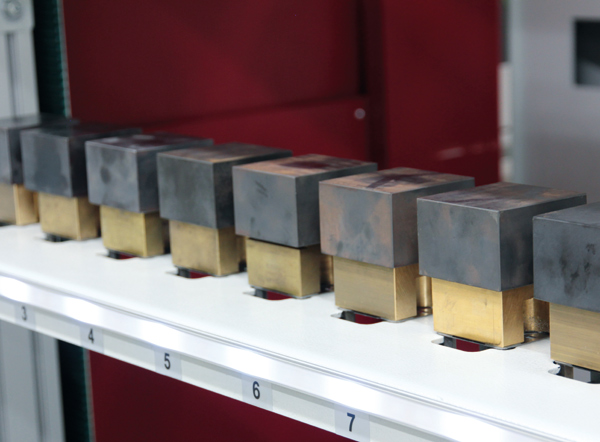

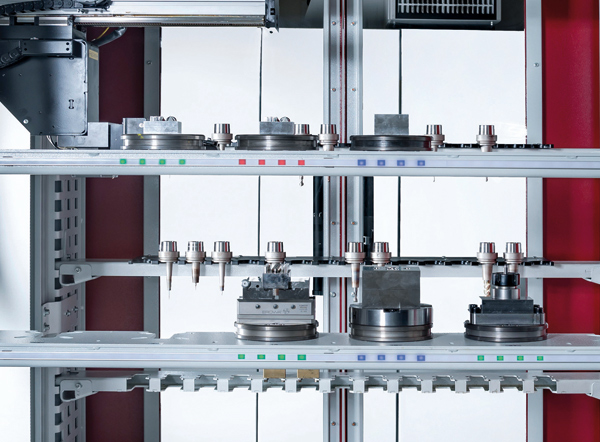

LED Status Indicator

The shelves of the magazines may be equipped with LED’s for depicting the status of the workpieces:

not machined /

finished with good quality /

finished but not okay /

waiting for manual operation /

in process /

others

Similar status indications with LED technology are also available for external cutting tools.

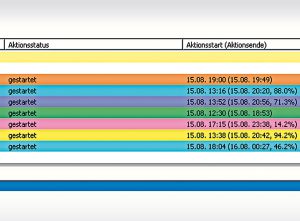

Calculation of the machining progress

In the Status Monitor as well as in the RMSMain the machining progress and the expected completion of the machining may be looked at for every machine at any time.

Priorities

Jobs and their priorities just like blocking and freeing of jobs are defined with few mouse clicks only.

Central data base

All data is stored in one secured data base system only. Full data consistency prevents errors, which might result from outdated or copied data.

Consistent geometry data

Zero point data or preset values for electrodes may be measured and used for subsequent machining operations.

RMSMain for workshop planning

RMSMain can also be used for the planning of the work (priorities) in individual not automated machines.

Interfaces to PPS and ERP systems

The XML based interface can easily be used for any desired PPS or ERP system, amongst others Beosys, IKOffice, Hummingbird Systems or SAP.

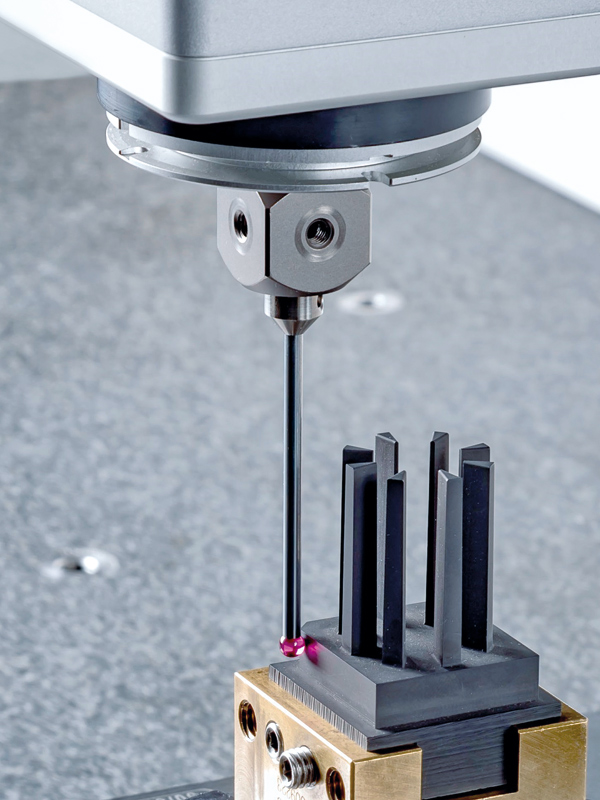

Quality control

Especially simple to use is the Roeders specific takeover of measuring points into a job for quality control. Cumbersome programming is not necessary. A graphic 3D-PDF file is generated as measuring protocol of this “in-machine-verification”.

Intelligent reaction to malfunctions

In case of a malfunction in a machine the automation continues operating and serving still available machines in a cell and respecting the priorities.

SMS/E‑mail

In case of malfunctions or errors an SMS or E‑mail is sent to defined receivers.

Energy management

RMSMain controls the machines for optimal energy saving. After completion of the last job for a machine the machine is turned off. If needed, a machine is turned on at a certain, programmed time for example one hour before the shift starts or when new jobs for a machine exist.

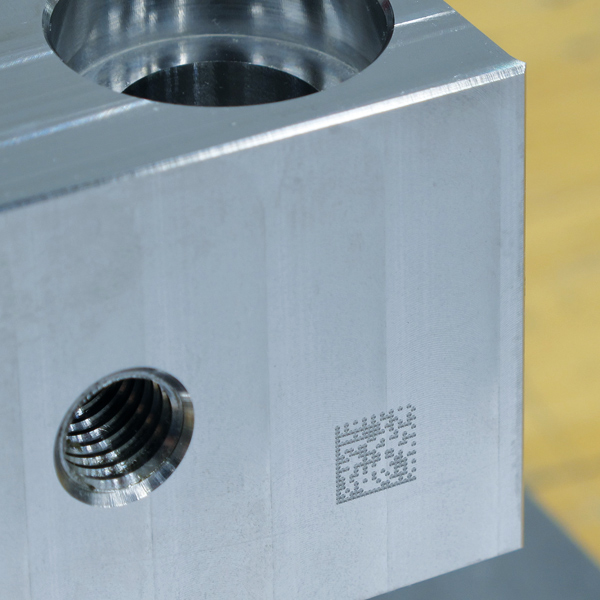

Printing of labels

In order to clearly mark a workpiece after it is taken off of the pallet with Chip-ID labels may be printed. Alternatively a data matrix code may be engraved directly into the workpiece at the end of a machining operation. The data matrix code is generated automatically from a text defined in the job. Labels may also be printed for marking tool holders, optionally also with data matrix code.