Roeders: 25 Years Of Experience

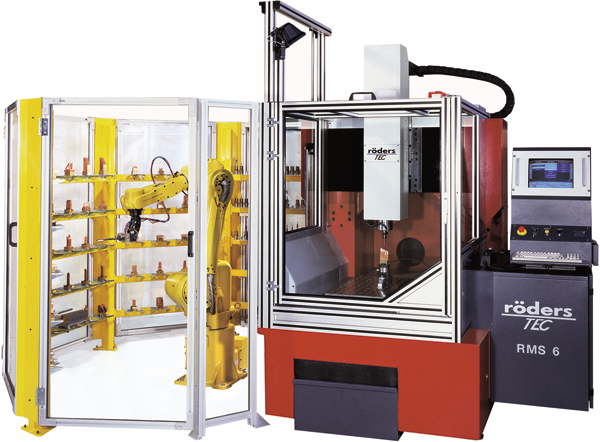

With the introduction of High Speed Cutting in the 1990’s productivity especially for manufacturing complex moulds was raised tremendously. Consequently customers started asking for solutions for an unmanned operation of the machines by automation. Already in 1995 Roeders sold the first automated machines for a 24 hour operation, 7 days a week.

Since then, Roeders has installed more than 500 solutions for automation. Hardware and software have been developed continuously over the years. Today numerous devices for the automation and an extremely easy to operate, in the sense of industry 4.0 fully data consistent software are available for achieving highest efficiency.

From practice for practice

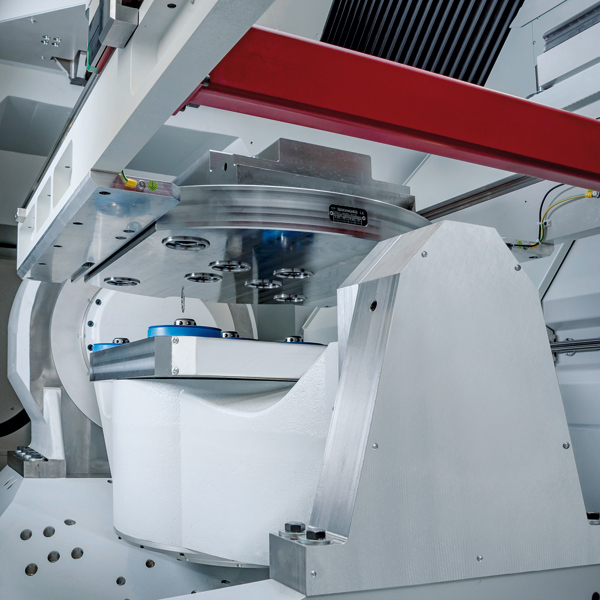

Of course Roeders uses in its own blow mould production not only High Speed Cutting machines made by Roeders but also Roeders own solutions for automation. Machining cells with up to 7 High Speed Cutting machines are served by a robot on a rail with workpieces and tools around the clock. Thus highest productivity is reached in a very competitive market segment. Likewise as for the development of the machines the Roeders blow mould production is the steady test environment for the Roeders automation in daily practice, in which the Roeders automation solutions are optimized in all details. This ensures very high reliability.

Updates also for Roeders automation solutions

Many customers of Roeders High Speed Cutting machines appreciate the update-service of Roeders for the NC control. Such kind of update-service is also available for the automation software from Roeders. The steadily growing functionality of the Roeders software may be taken over anytime.