Tool Management – For Highest Efficiency

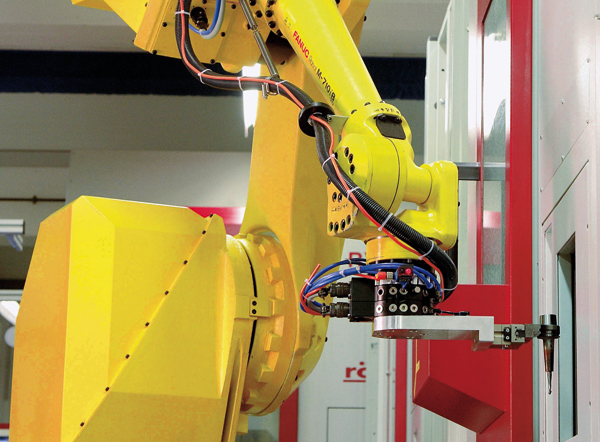

Roeders is the leader in tool management for automation. The automation, if intended for, serves the machines not only with workpieces but also with tools directly into the machine tool changer. With this the machine tool changer is extended with cost efficient external tool places in the central magazine of the automation. The tool changers in the machines may be kept smaller and more cost-effective. The operator does not need to worry about the machine tool changers. The supply with tools to the machines and back in a cell solely takes place from the central magazine.

Forward-looking supply

The automation loads forward-looking required tools into the machine tool changer and unloads tools not needed anymore or worn while a workpiece is machined.

Tool-ID

The tools are put on pre-defined places in the magazine. Each tool type has a pre-defined place in the magazine. Also sister tools are possible. Higher security against mistakes may be achieved by using a data matrix code. Already when the cutter is put into the tool holder the code on the tool holder is read and therewith the tool type defined. The tool holder with the data matrix code may be put on any place in the magazine. The automation scans and recognizes it.

Extra wear area

Worn tools are not put back to their pre-defined places in the magazine but into an extra wear area. A quick visual check is enough to deter-mine, whether any worn tools need to be replaced.

Central data base

All tool data in a workshop, also for several automated cells, is stored in one data base system. This allows checking any time, where a tool may be found and what its status is. Data for tool types may easily and centrally be edited.

Tool cache functionality

The operator determines, which tool types are used often and therefore should always be available in the machine tool changer. The automation consequently implements this. In case such a tool is worn the automation immediately replaces it by a sister tool. The remaining tool places in the machine tool changers are used to supply the machine with tools needed for the current operation, if needed also with special tools. This minimizes the number of tool changes between the machine tool changer and the magazine.