Data Consistency – The Back Bone of Industry 4.0

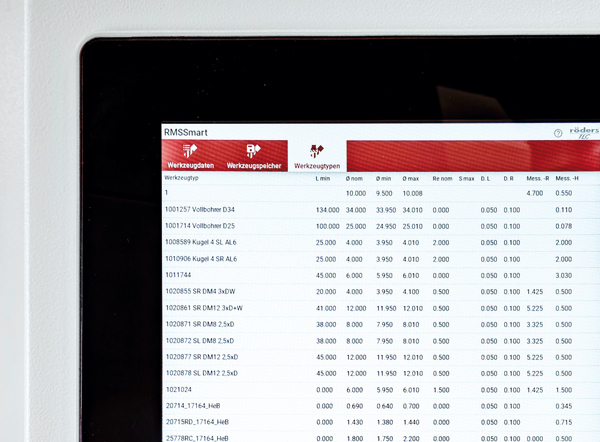

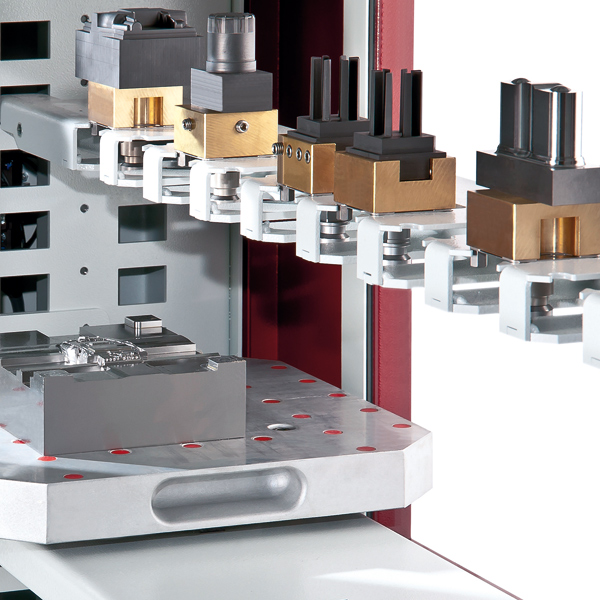

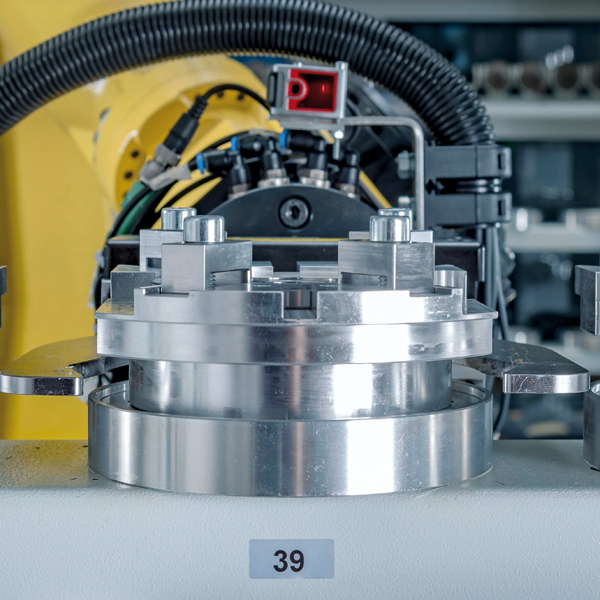

An essential feature of Industry 4.0 compatible solutions is full data consistency. In a permanently changing production environment any copy of data is immediately outdated. Therefore, access to original data becomes decisive for avoidance of errors and highest productivity. Roeders consequently implements this by allowing access to original data in the machines and automation anytime from anywhere. All data is stored in a central data base system.

Real time information

With a web-based interface tool data of the machines may directly be read. The CAM-programmer as well as the production manager can verify the actual condition and availability of the tools in each machine and in the automation via browser at their personal computer in real time.

Web-based check of machine condition

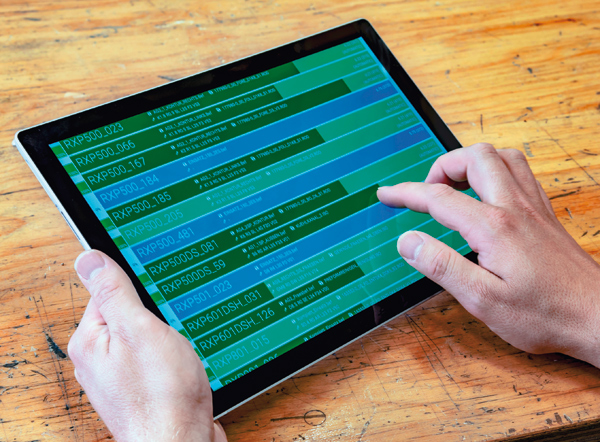

Also web-based, the condition of the machines in the workshop may be checked.

- What is being machined?

- Is there a disruption?

- How is the machining progress?

- How much longer will the machining time be?

- Etc.

Of course access to this data is only allowed for authorized staff. Access rights may be managed as required.

In view Anytime

Status and location of each workpiece, for example electrodes, in an automation cell can be checked from any workplace.

Roeders is one of the leading partners in realizing the umati interface. No matter which machine data is requested from a superordinate level for evaluation, checking or controlling, Roeders gives access to this data through the standardized umati interface.