Control Technology

PC-based control

- Very simple user interface

- USB interface standard

- 19” TFT screen standard

- NC-programs in ISO-format or Heidenhain®#-format (with limited scope), mixed code also possible

- Compatible with INDUSTRY 4.0

Vibration monitoring of the spindle

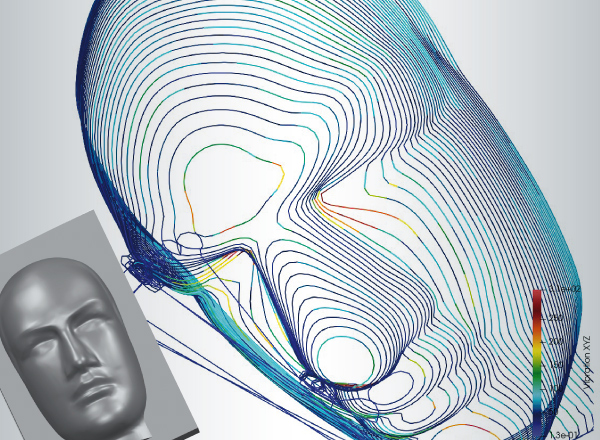

The use of high-speed spindles requires a limitation of the maximum spindle load in order to avoid bearing damage or a severe reduction in service life. Optionally, the spindles can be equipped with vibration sensors. A function in the control can be activated that automatically reduces the feed and, if necessary, the RPM of the spindle in the event of high vibrations. In addition, a coloured graphic illustration of the vibrations along the milling path is possible. As a result, any areas in the milling path with high vibrations can easily be identified and can safely be avoided in recurring machining processes by adapting the CAM programming.

Roeders is partner of the umati initiative of the German machine tool association VDW (umati = universal machine tool interface). The umati interface enables a standardized data transfer to the machines of numerous suppliers. umati is an essential step towards industry 4.0.

Control technology optimised for HSC

Outstanding characteristics of the Roeders RMS6 control:

- Block processing time < 0.1 ms

- Look ahead > 10,000 blocks

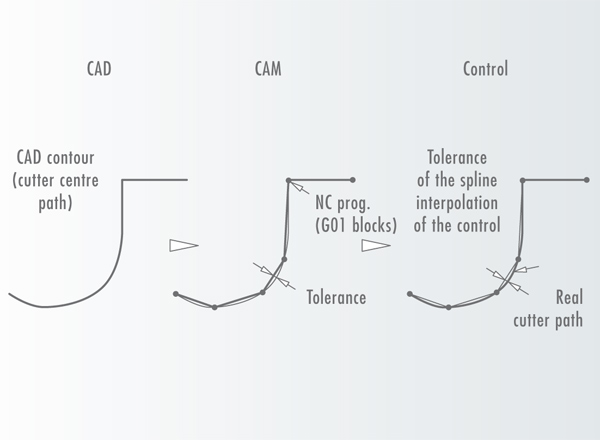

- Continuously improved spline interpolation

Performance increase through control updates

Newest control versions also for older machines(from year of manufacture 1995) available at low cost with the special Roeders update service

> Higher precision, better surface quality and significantly shorter machining times

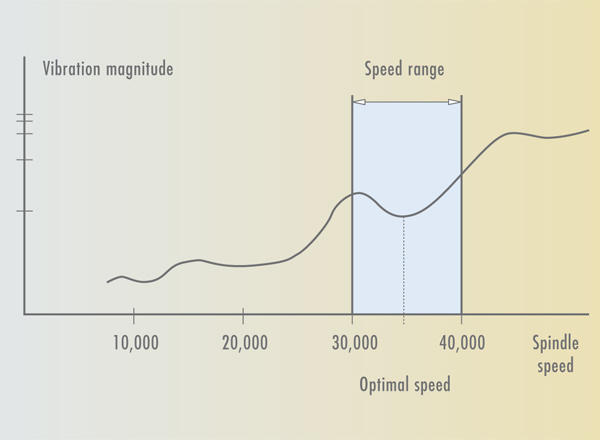

Automatic minimisation of vibrations

Automatic spindle speed optimisation by the machine within a user-selectable range in order to minimise vibrations and achieve the highest possible surface quality; patent pending

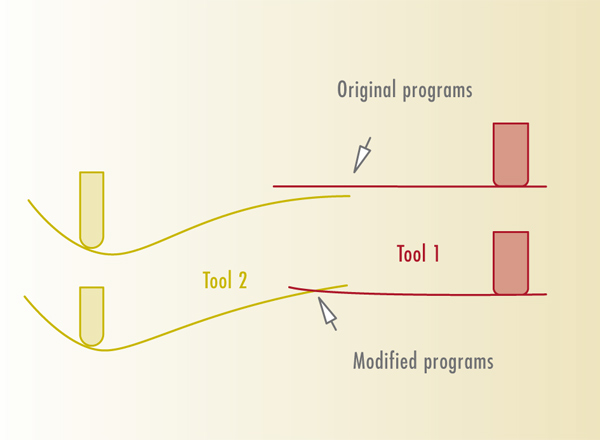

Tangential transitions

Patented function to avoid offsets in transitional areas if several different tools are used for machining

- Automatic modification of the machining programs for tangential transitions

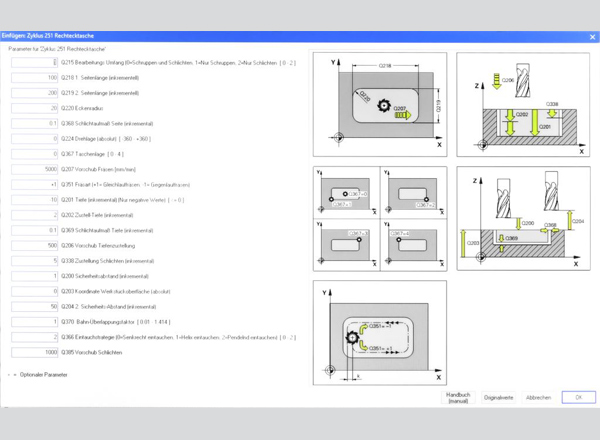

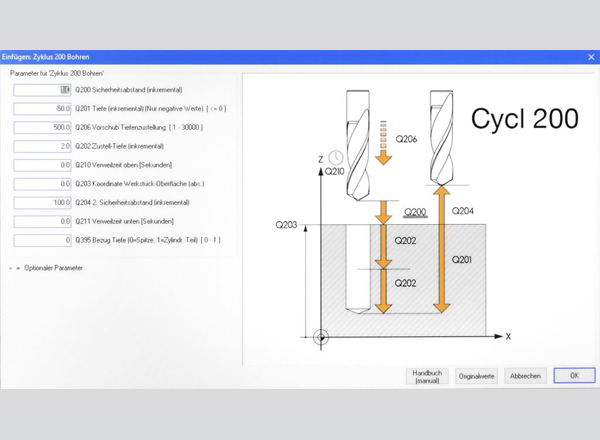

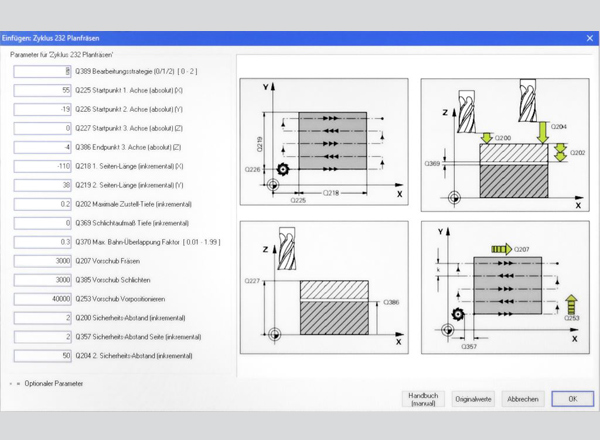

Post-processors

- Simple individual programing of postprocessors for all CAD/CAM-systems with the help of the Roeders postprocessor handbook

- Standard postprocessors available at Roeders

- Complete output of all NC-parameters by the CAM-system

→Programing at the machine control not necessary

- Processing of ISO-NC-programs (G‑code) or Heidenhain®#-NC-programs (with limited scope) possible

- very short familiarization time

- Changeover between Roeders control and Fanuc, Siemens, Heidenhain or others very easy for operators, because the familiar NC-programing language does not change

- Auch gemischte Verwendung von ISO- und Heidenhain®#-Befehlen erlaubtAlso a mixed use of ISO-NC-commands and Heidenhain®#-NC-commands is allowed

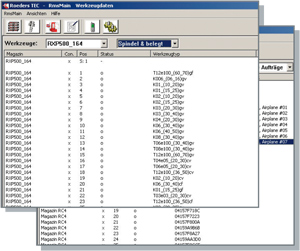

Optimised use of tools

Numerous functions for optimised use of tools

- Sister tools

- Wear criteria

- Maximum tool life travel

- Measurement strategies

- Geometry identification and test

- etc.

Further control functions

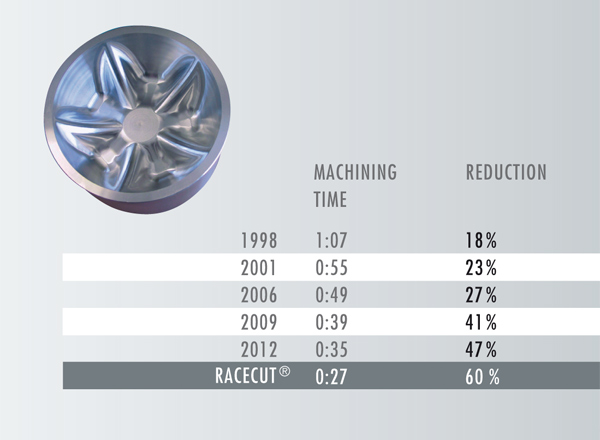

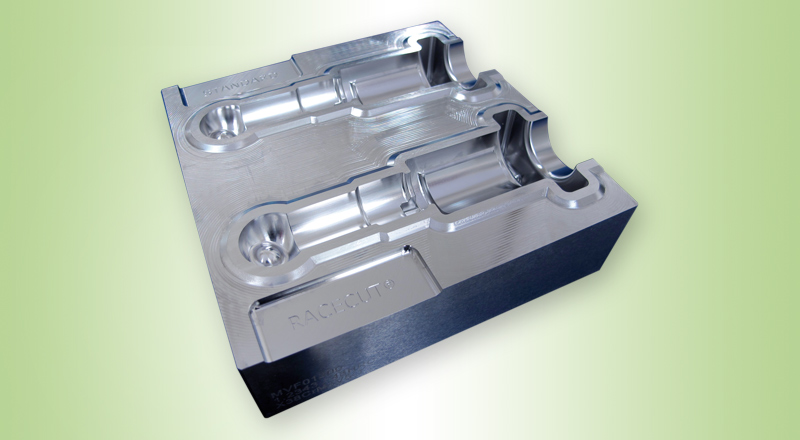

- RACECUT® – Performance boost in machining 3D contours

- 32 kHz drive control frequency and an optimized tool path planning in the control lead to significant reductions of machining times, up to 20% while surface quality and precision remain equal

- Since the energy consumption of the machine is relatively constant regardless of the selected dynamics, the energy saving is of the same dimension

#Heidenhain is the registered trade mark of the Dr. Johannes Heidenhain GmbH.