Gears

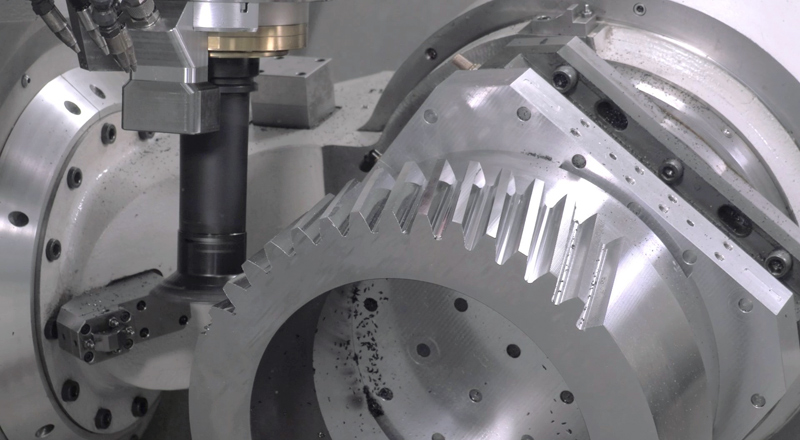

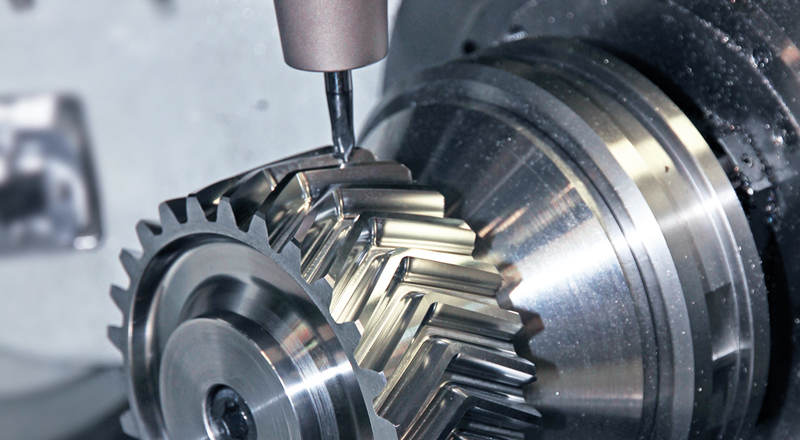

On the modern 5‑axis Roeders High Speed Cutting machines different gears may be produced by milling and grinding also in very hard materials with very high precision. Machine size and milling spindle are chosen from a large product range for adapting to the requirements of the individual gear production with highest efficiency. With automation, for example the RCS devices, extremely low production costs are achieved, also for single pieces.

The programming of the gears is accomplished with the especially for gear production developed software from the EUKLID CAD/CAM AG, very simple and fast. Roeders offers full support of the complete process chain, programming and production.

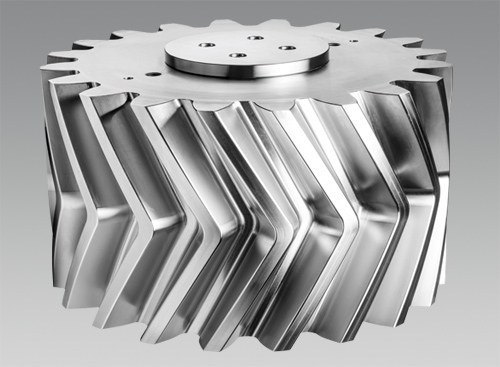

Gear

Machined on RXU1001DSH, ø 450 mm, 60 HRC