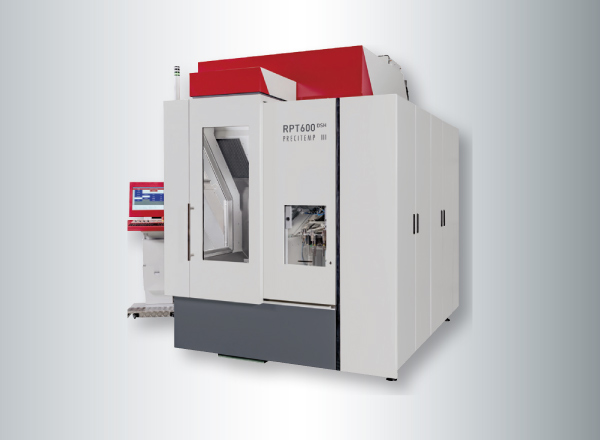

Roeders Precision Technologies –

RPT600DSH

Milling, grinding, measuring in one machine

- Several years of groundbreaking developments are the foundation of the RPT series

- Maximum precision, even better surfaces and shorter processing times lead to significant increases in productivity in mould and die making as well as production applications

- PRECITEMP®-Technology in the different levels I, II and III for highest precision also if ambient temperatures of the machine are not stable

- All options known from the RXP series are fully available

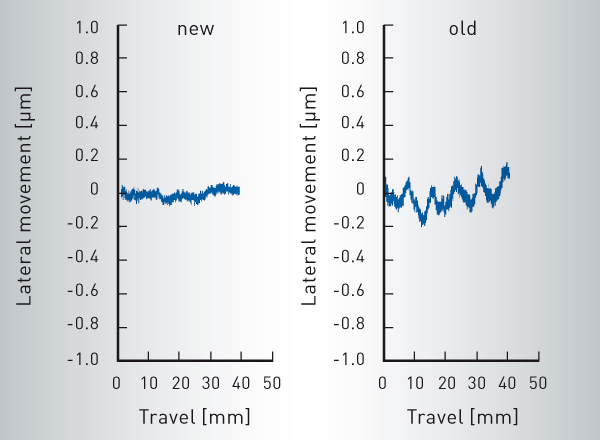

of the linear guideways

The disadvantage of roller guideways compared to hydrostatic guideways is that they run less smoothly. In this regard, a quantum leap could be achieved in cooperation with a well-known roller guideway manufacturer, which results in considerable advantages, especially for high surface requirements. The generous dimensioning of the guideways ensures long durability.

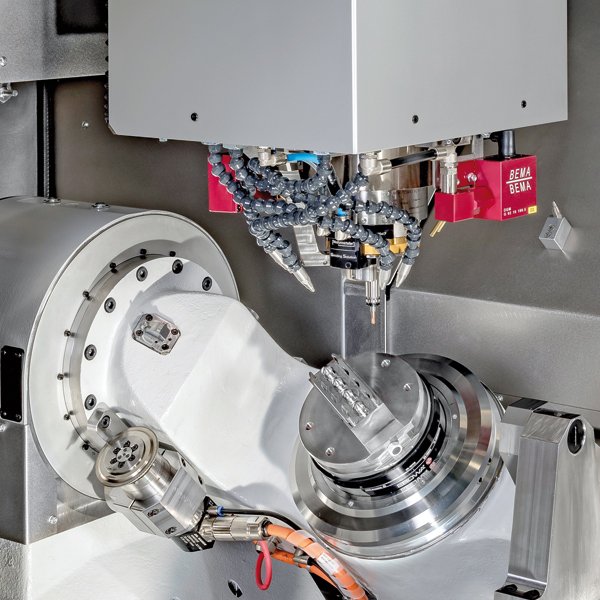

The workpiece is placed in the center of the swivel and rotary axes. As a result, the linear axes have to make substantial less compensating movements for 5‑axis machining. The processing times are significantly reduced and the workpieces are more precise.

The RPT series was designed for durability and energy efficiency down to the last detail.

The control cabinet is usually integrated into the machine tool. For the RPT series, the electrical cabinet stands alone next to the machine so that electronic components are not affected by vibrations from machining or the dynamics of the machine. In addition, the high weight of the machine and the large distance between the machine feet ensure low stress despite the high dynamics of the axes. Numerous measures have been undertaken to significantly reduce energy consumption, e.g. a power-controlled cooling unit.

| Technical data | |

|---|---|

| Machining range | 470 mm x 530 mm x 300 mm |

| Swivelling range | +/- 115 degrees |

| Rotation range | Almost unlimited |

| Table size | 250 mm round |

| Clamping unit | Erowa ITS148 PowerChuck / System 3R Magnum / Parotec Power Grip 160 |

| Workpiece weight | max. 60 kg |

| Feed | 0–60,000 mm/min |

| Milling spindle (standard) | 42,000 rpm, 14 kW, HSK E40, maximum tool diameter 16 mm, others on request |

| Tool changer | 42 or 87 places for HSK E40, optional larger changer available, integrated measuring laser |

| Chip disposal | With 2 screws into chip box behind the machine or with additional chip conveyor |

| Machine weight | ~9.3 t |

| Required space | W 2200 mm x L 2500 mm x H 2720 mm |

- Very efficient due to high stiffness and optimum layout of the mass inertia

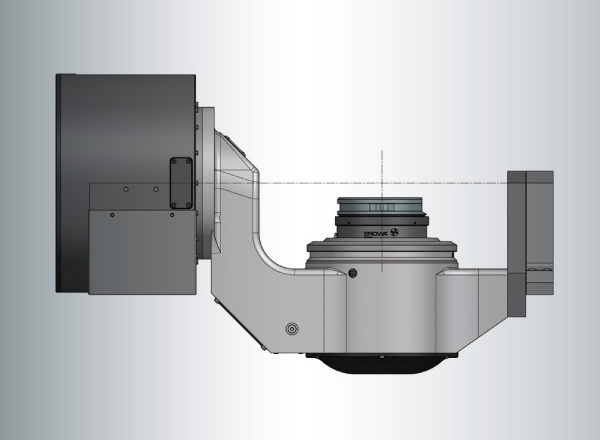

- Two-sided support of the C‑axis for high stability and precision

- High resolution optical encoders in all axes

- Powerful wear-free direct drives in all axes

- Special Roeders 5‑axis geometry compensation for high precision, also at long lasting machining operations

- Precise temperature control of the machine elements

- For dynamic decoupling, the swivelling direction is at right angles to the X axis

- Windows very close to the machining area, visible from two sides

- Chucks for different pallet systems can be integrated into the C‑table