Tolerances halved!

New RPT series achieves significantly higher precision with PRECITEMP® and NANOTOL® Technology

The RPT machines from Roeders are not only visually different from their predecessors. The machines are also built with significantly improved technologies. As a result, previously unthinkable tolerances are now possible for many applications. Compared to the very precise RXP series Roeders again has made a quantum leap.

NANOTOL® — for highest precision of the linear guideways

With the NANOTOL® technology, Roeders has raised the precision and running behaviour of the guideways in the linear axes of the RPT machines to a new level. The tolerances in the running behaviour of the axis carriages are so small that they no longer have any influence on the machining result because other parameters such as the running concentricity of the tool etc. play a greater role. The diagram shows the significant difference between the previous and new guideway technology with NANOTOL®.

Residual errors in the straightness of the guideways and positioning uncertainties of the optical scale are measured over the entire travel of the axis with the high-precision XM60 laser from Renishaw and compensated for by the NC control system. In this way, exceptional accuracy and straightness of the linear axes are achieved.

PRECITEMP® — high precision in case of temperature fluctuations in the workshop

In most applications, temperature fluctuations in the workshop are the main cause of inaccuracies during machining. This also applies to air-conditioned workshops, where the temperature often only fluctuates by a few degrees. This has therefore been a focus of development at Roeders in recent years. The result is the unique PRECITEMP® technology, which enables a temperature-resistant optimization of the machine for maximum precision with a graduated concept depending on the requirements. The machine has been viewed holistically and a comprehensive solution for temperature control of all machine components has been developed. Minimal residual errors are eliminated with software compensation.

Heat sources in the machine such as motors, main spindle, linear guideways (optional) and rotary axis bearings are also tempered with high precision. As a result, the zero point of the machine is within +/- 1 µm, even with temperature fluctuations in the workshop of up to +/- 3°C.

3‑axis-machining and jig grinding in XXL-format

The new RXU2000 from Roeders achieves maximum precision when workpieces and moulds with particularly large dimensions have to be machined. Designed for exceptional accuracy combined with high performance in machining hardened materials, the machine has a working area of 2,000 x 1,800 x 800 mm. The work table is designed for loads of up to 5.0 t. The Z‑axis stroke has been intentionally limited in order to ensure maximum accuracy.

The RXU 2000 is suited for 3D milling as well as for jig grinding, vertical grinding or profile grinding. This combination of operations in one set-up on the same machine is particularly interesting for many jobs in machine production and mould making.

Linear direct drives in all axes as well as a sophisticated temperature management system for the entire machine ensure the highest possible accuracy, even during long machining jobs. Accuracies of less than 5 µm can be achieved in the entire working area, as well as a roundness of 1–2 µm depending on the size of the bore.

The RXU2000 is particularly suitable for the production of:

- Large mould plates, e.g. for stamping dies

- Large, flat injection moulds with fine contours (e.g. for seals), which have to be machined with relatively small tools

- Machine components, e.g. guide rails

- Large high-precision workpieces

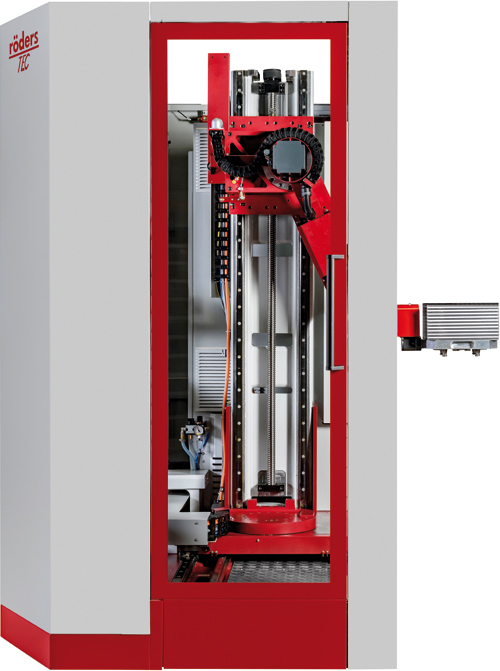

Reliable fully automated production

RCF 150 — linear very compact machine automation for one or several machines placed in a row:

- Only 1.5 m wide including shelves

- Max. workpiece weight 150 kg

- Gripper change for different pallet types and tools

- quickly installed due to modular design

- easy to expand anytime

Cylindricity < 0.5 µm

A 24 cavity injection mould for lenses for mobile phones had been jig ground on a RHP500 machine with highest precision possible. This application became especially challenging, because the holes had only 8 mm diameter, the area to be jig ground began 15 mm below the mould surface and reached a depth of 45 mm. In consequence, the holes had to be ground cylindrical with highest precision on a total length of 30 mm. The requested cylindricity of 0.5 µm was achieved on all 24 cavities.

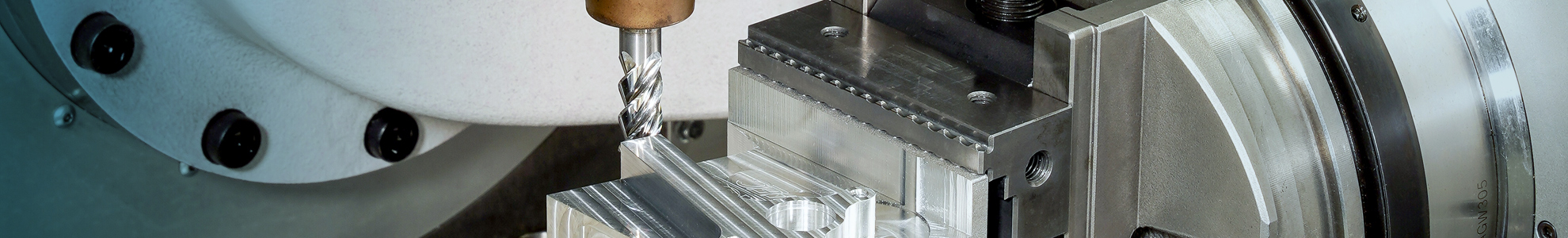

Milling and Grinding

Cutting or grinding tools with up to 200 mm diameter may automatically be changed into the main spindle by a newly developed tool changer, which is placed below the bridge of the machine. For each tool an adjusted cooling supply is changed as well, which allows perfect cooling where needed for the cutting process.

Machining with a large grinding wheel with adjusted, likewise automatically changed cooling supply for the grinding process with large coolant volume

Roeders is partner of umati initiative

Roeders is partner of the umati initiative of the German machine tool association VDW (umati = universal machine tool interface).

Moulds for liquid silicone rubber (LSR)

Parting surfaces of injection moulds for liquid silicone rubber (LSR) are machined with high precision to final dimensions. No rework is necessary. The moulds are directly used for flash-free production.

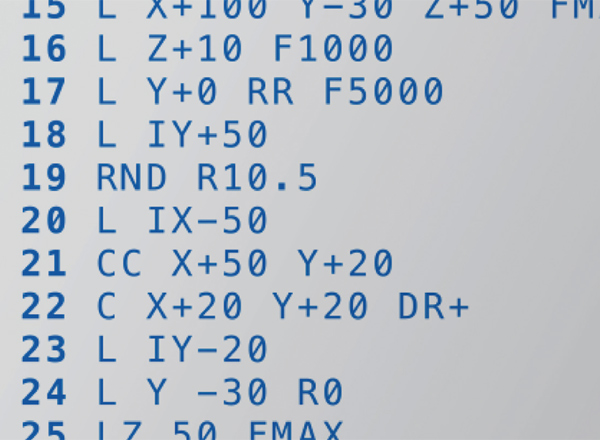

HEIDENHAIN®# and ISO-Code (G‑Code)

For minimizing training periods and facilitating the change of operators among machines with different NC-Controls, Roeders machines may be programmed in HEIDENHAIN®#-NC-Code (with limited scope) or ISO-Code (G‑Code). The NC-Program is created with simple macros at the control. Operators knowing the NC-commands in the respective code do not need extra training.

#Heidenhain is the registered trade mark of the Dr. Johannes Heidenhain GmbH

Reflector, material ELMAX 58 HRC

Machining results:

Precision +/- 1 µm

Surface quality Ra 0.010 µm

New possibilities in the watch industry

The combination of high precision air bearing spindles running up to 90000 rpm with the linear motor direct drive technology of the Röders HSC machines allow for up to now unknown qualities in the watch industry. On the exhibition EPHJ in Geneva specialists were convinced of the superior quality directly at the machine. With the long-standing competence of Röders in automation the machine may be adapted to a highly efficient manufacturing process at the customer.